Industrial coatings for extreme environments play a critical role in protecting machines, tools, and components that operate under intense heat, pressure, corrosion, or abrasive conditions. From manufacturing plants to aerospace, oil & gas, and heavy engineering, these coatings quietly extend equipment life, reduce downtime, and improve performance when conditions are anything but normal.

In India’s rapidly growing industrial sector, companies are increasingly turning to advanced solutions like pvd coating service in india to handle harsh operating environments without constantly replacing expensive components. Let’s explore what makes industrial coatings essential, how they work, and why they matter more than ever today.

What Are Extreme Environments in Industrial Applications?

An “extreme environment” doesn’t just mean high temperature. In industrial terms, it includes conditions such as:

- Extremely high or low temperatures

- Constant friction and mechanical wear

- Exposure to chemicals, acids, or solvents

- High pressure and heavy loads

- Moisture, humidity, and corrosion

- Dust, debris, and abrasive particles

These conditions can quickly degrade unprotected metal surfaces. Cracks form, corrosion spreads, and tools lose precision. This is exactly where industrial coatings step in.

Why Industrial Coatings Are No Longer Optional

In the past, frequent part replacement was seen as a cost of doing business. Today, with tighter margins and higher performance demands, that mindset no longer works.

Industrial coatings offer clear advantages:

- Longer component life

- Improved wear and corrosion resistance

- Better thermal stability

- Lower maintenance costs

- Consistent performance over time

Instead of replacing tools or machine parts every few months, coated components can last significantly longer—even in punishing environments.

Common Types of Industrial Coatings Used in Harsh Conditions

Different environments demand different coating technologies. Some of the most widely used industrial coatings include:

Thermal Barrier Coatings

Designed to protect components from extreme heat, especially in turbines and engines.

Anti-Corrosion Coatings

Used in marine, chemical, and oil & gas industries to prevent rust and chemical damage.

Wear-Resistant Coatings

Ideal for cutting tools, dies, and mechanical parts exposed to constant friction.

Thin-Film PVD Coatings

Known for their durability, precision, and eco-friendly process—perfect for modern manufacturing.

What Is PVD Coating and Why Is It So Popular?

At this point, many engineers and manufacturers ask, what is pvd coating and why is it gaining so much attention?

PVD (Physical Vapor Deposition) coating is a vacuum-based process where a thin, hard layer of material is deposited onto a surface. This layer bonds at an atomic level, making it extremely durable without changing the part’s dimensions.

PVD coatings are valued because they:

- Are extremely hard and wear-resistant

- Handle high temperatures well

- Reduce friction

- Improve surface finish

- Are environmentally friendly compared to traditional coatings

Because of these benefits, PVD coatings are widely used in tooling, automotive, aerospace, medical, and industrial manufacturing.

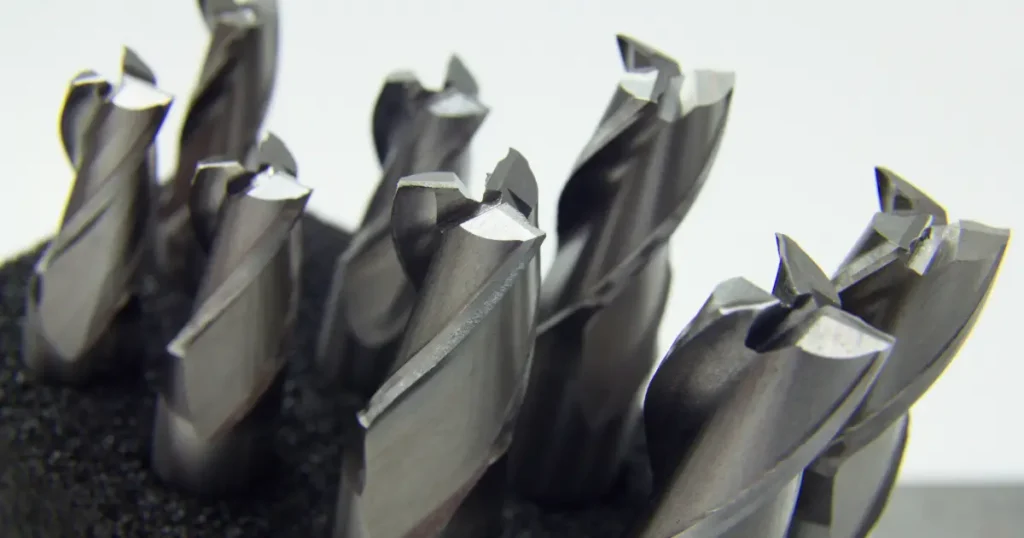

Industrial Coatings for Cutting Tools and Dies

Cutting tools and dies face some of the harshest working conditions—high speed, intense heat, and constant contact with hard materials.

PVD Coating for Cutting Tools

Using pvd coating for cutting tools significantly improves tool life, cutting speed, and surface finish. Coated tools experience less heat buildup and reduced wear, allowing manufacturers to maintain consistent quality while lowering tool replacement costs.

PVD Coating for Dies in India

Similarly, Pvd coating for dies in india is becoming essential in stamping, forming, and molding industries. Coated dies resist galling, cracking, and surface damage, even during high-volume production runs.

Industries That Rely on Industrial Coatings for Extreme Environments

Industrial coatings are not limited to one sector. They are widely used across:

- Automotive and auto components

- Aerospace and defense

- Oil & gas and petrochemicals

- Heavy engineering and machinery

- Power generation

- Medical and surgical tools

In each case, coatings act as a silent protector—keeping operations running smoothly even when conditions push materials to their limits.

Choosing the Right Coating Solution

Not all coatings are the same, and choosing the wrong one can lead to poor performance or early failure. Key factors to consider include:

- Operating temperature

- Type of wear (abrasion, adhesion, erosion)

- Exposure to chemicals or moisture

- Load and pressure conditions

- Required surface finish

Working with an experienced coating provider ensures the coating is matched perfectly to the application.

For a deeper technical understanding of coating technologies, you can explore this detailed guide on advanced surface engineering solutions from an authoritative materials science resource like ASM International.

The Role of Indian PVD Coating Providers

India has seen rapid growth in advanced surface engineering, with modern facilities now matching global standards. A reliable pvd coating company in India can offer customized solutions, faster turnaround times, and cost-effective services without compromising on quality.

This local expertise helps Indian manufacturers stay competitive in global markets while meeting demanding performance requirements.

Conclusion: Coatings That Stand Up to the Toughest Conditions

Industrial coatings for extreme environments are no longer a luxury—they are a necessity for industries that demand reliability, efficiency, and long service life. Whether it’s resisting heat, fighting corrosion, or reducing wear, the right coating can dramatically improve performance and reduce costs.

By partnering with a trusted pvd coating company in India, manufacturers can access advanced solutions tailored to their toughest challenges. When done right, industrial coatings don’t just protect surfaces—they protect productivity, quality, and long-term success.

Related Articles on PVD Coatings

- PVD coating process explained

- Titanium nitride (TiN) coating for industrial applications

- Ultimate guide to PVD coating for industrial components

- Difference between PVD coating and powder coating

- Coatings for High-Performance Pumps and Compressors

FAQs: Industrial Coatings for Extreme Environments

Industrial coatings protect components from wear, corrosion, heat, and chemical exposure, especially in harsh operating conditions.

Yes, PVD coatings perform exceptionally well under high temperatures, friction, and mechanical stress.

Automotive, aerospace, oil & gas, heavy engineering, medical tools, and power generation industries benefit the most.

PVD-coated tools can last several times longer than uncoated tools, depending on the application and operating conditions.

Yes, PVD coating is considered eco-friendly because it produces minimal waste and does not use harmful chemicals.

Comments are closed