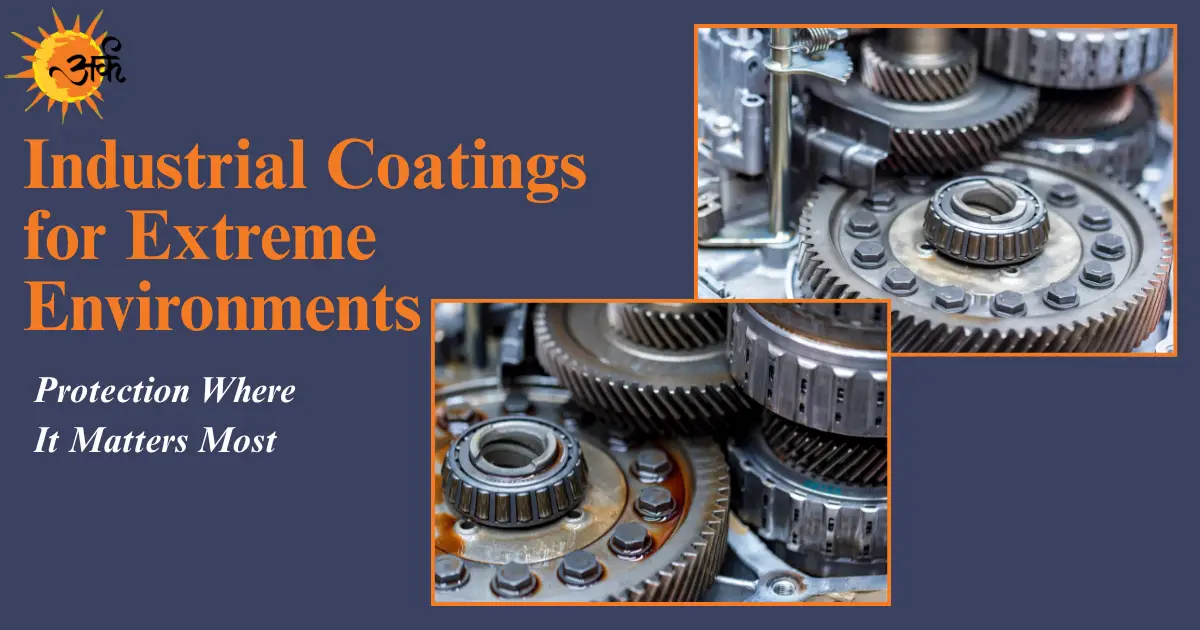

Energy Sector Coating Solutions India: Enhancing Performance and Longevity

Energy sector coating solutions India are becoming increasingly important as power generation, oil & gas, and renewable energy industries demand higher efficiency, longer equipment life, and lower maintenance costs. From thermal power plants to offshore oil rigs and renewable energy

READ MORE

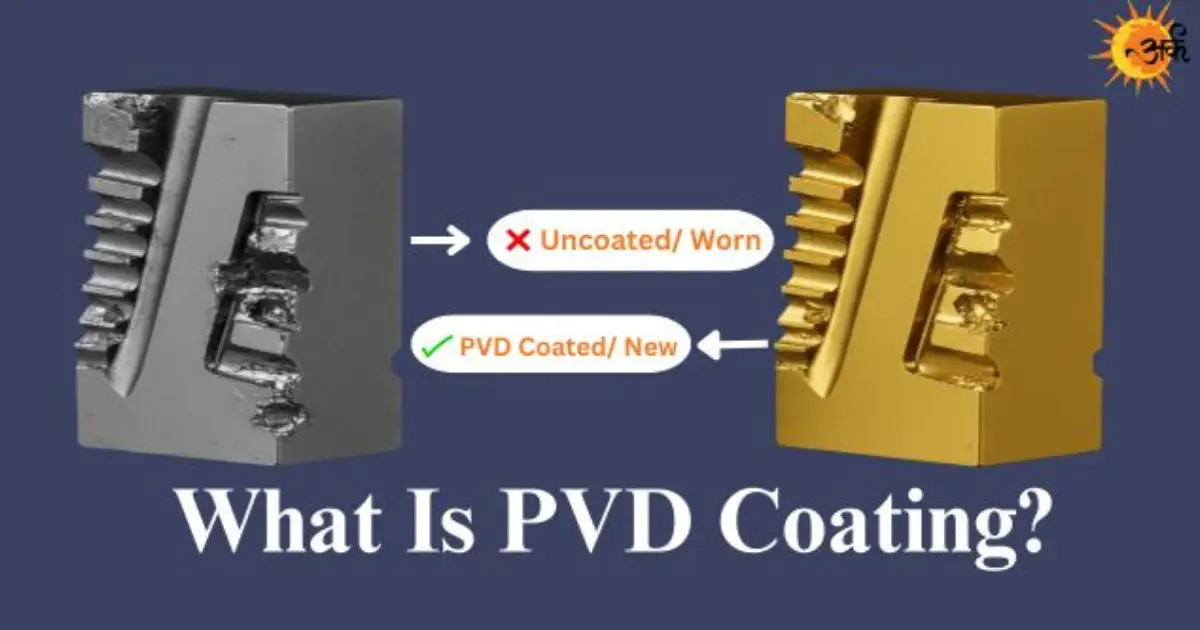

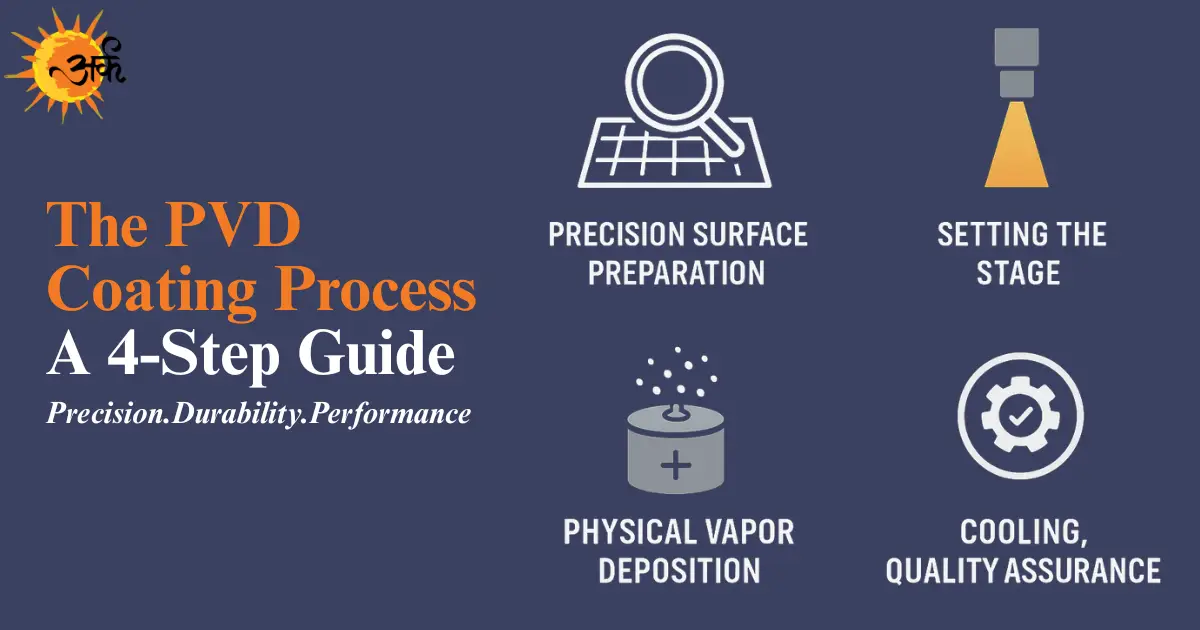

PVD Coating

PVD Coating