Why Pumps and Compressors Need Advanced Coatings

Coatings for high performance pumps and compressors are essential because these machines operate in some of the toughest industrial conditions. For manufacturers seeking reliable surface protection, a professional PVD coating service in India plays a key role in improving durability and performance.

To meet modern industrial performance requirements, manufacturers increasingly rely on advanced coating solutions for pumps and compressors. The right coating protects critical components, improves operating efficiency, reduces unplanned downtime, and significantly extends service life. This article explains why coatings matter, which pump and compressor components benefit the most, and how PVD coatings provide a reliable solution for high-performance applications.

Pumps and compressors often operate non-stop in environments where uncoated metal surfaces struggle to survive. Common challenges include:

- Abrasive wear caused by solid particles in fluids or gases

- Corrosion due to chemicals, moisture, or aggressive media

- Friction and heat generation, leading to energy loss

- Surface fatigue, resulting in cracks and component failure

Without protective coatings, components wear out faster, maintenance costs rise, and production interruptions become frequent. This is why wear-resistant and corrosion-resistant coatings for pumps and compressors are now considered essential rather than optional.

Critical Pump and Compressor Components That Require Coatings

Not all parts experience the same level of stress. Coating the most exposed components delivers the highest performance gains.

Commonly Coated Components Include:

- Impellers – exposed to erosion, cavitation, and corrosion

- Shafts – suffer from wear, friction, and chemical attack

- Rotors – require smooth surfaces for efficiency and balance

- Pistons and valve plates – experience sliding wear and pressure loading

- Bearings and sealing surfaces – demand low friction and durability

For components exposed to high temperatures and severe wear, such as impellers, shafts, and rotors, AlCrN PVD coatings provide excellent oxidation resistance and long-term surface protection.

Types of Coatings Used for Pumps and Compressors

Several coating technologies are used in pump and compressor applications. Each serves a different purpose depending on operating conditions.

PVD Coatings (Physical Vapor Deposition)

PVD coatings are widely used for high-performance pump and compressor components because they offer:

- High surface hardness

- Low friction

- Excellent wear resistance

- Strong adhesion to metal substrates

Common PVD coatings include TiN, TiAlN, and CrN, which are ideal for precision components where dimensional accuracy matters. For readers new to the technology, our guide on What is PVD coating explains the process, benefits, and industrial applications in detail.

Thermal Spray Coatings

Thermal spray coatings create thick protective layers and are often used for large components exposed to severe erosion or corrosion.

Hard Chrome Plating

Hard chrome provides wear resistance but faces environmental restrictions and cracking issues over time.

Ceramic Coatings

Ceramic coatings offer thermal and chemical resistance but may lack flexibility for dynamic components.

Among these options, PVD coatings for pumps and compressors stand out for applications that require precision, durability, and efficiency.

Benefits of PVD Coatings for High-Performance Pumps and Compressors

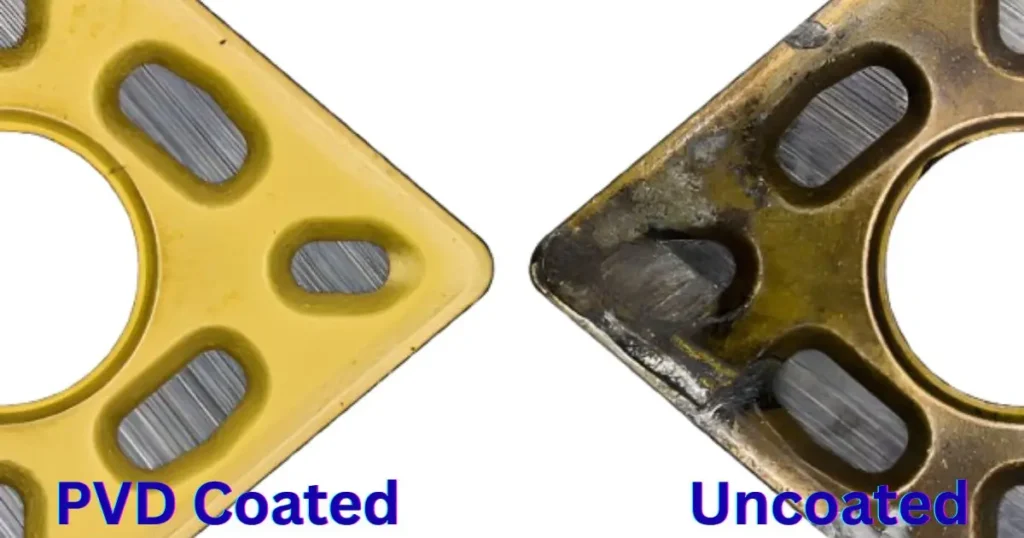

PVD coatings provide multiple performance advantages that directly impact productivity and cost savings. In high-load and high-speed pump and compressor applications, TiAlN PVD coatings help reduce friction, improve wear resistance, and maintain stable performance over long operating cycles.

Key Benefits Include:

- Improved wear resistance

Hard coatings protect components from abrasive and sliding wear. - Enhanced corrosion protection

Coatings act as a barrier against chemicals and moisture. - Reduced friction

Lower friction improves energy efficiency and reduces heat generation. - Longer service life

Coated parts last significantly longer than uncoated ones. - Stable performance under high load

PVD coatings maintain integrity even in demanding operating conditions.

These benefits make PVD coatings an ideal choice for industrial pump and compressor applications.

How Coatings Improve Energy Efficiency

Energy efficiency is a major concern in pump and compressor systems. Surface friction directly affects power consumption. Even small reductions in friction can lead to noticeable energy savings over time.

Low-friction coatings help:

- Reduce mechanical losses

- Maintain smooth fluid flow

- Prevent surface roughening due to wear

As a result, coated pumps and compressors operate more efficiently and require less energy to deliver the same output.

Industries That Use Coated Pumps and Compressors

Advanced coatings are used across many industries where reliability is critical.

Key Industries Include:

- Oil and gas

- Chemical processing

- Power generation

- Water and wastewater treatment

- HVAC and refrigeration

- Pharmaceuticals and food processing

In these sectors, downtime is costly, and coated components help ensure continuous and reliable operation.

Choosing the Right Coating for Pumps and Compressors

Selecting the right coating depends on several factors. A one-size-fits-all approach rarely works.

Important Considerations:

- Operating temperature

- Type of fluid or gas

- Presence of abrasive particles

- Load and rotational speed

- Base material of the component

Working with an experienced coating provider ensures the coating matches the application requirements and delivers long-term value.

Why PVD Coatings Are Ideal for Modern Pump and Compressor Systems

Modern pumps and compressors demand precision, efficiency, and reliability. PVD coatings meet these demands without altering component dimensions or compromising performance.

They provide a balanced combination of hardness, smoothness, and adhesion. This makes them suitable for both new components and refurbishment of worn parts. For manufacturers and maintenance teams, industrial PVD coatings offer a practical and cost-effective solution.

Conclusion

High-performance pumps and compressors operate under challenging conditions that accelerate wear, corrosion, and efficiency loss. Advanced coating solutions play a crucial role in protecting critical components and ensuring reliable operation.

Among available options, PVD coatings for high-performance pumps and compressors deliver excellent wear resistance, reduced friction, corrosion protection, and extended service life. By choosing the right coating and application method, industries can improve efficiency, reduce maintenance costs, and maximize equipment uptime.

Arka PVD Coating is a trusted PVD coating company in India, providing high-quality coating solutions for pump and compressor components.. Our team helps you select the right coating solution for your operating conditions and performance goals.

Related Articles on PVD Coatings

- PVD coating process explained

- Titanium nitride (TiN) coating for industrial applications

- Ultimate guide to PVD coating for industrial components

- Difference between PVD coating and powder coating

Frequently Asked Questions (FAQs)

PVD coatings such as TiN, TiAlN, and CrN are widely used because they offer excellent wear resistance, low friction, and strong adhesion without affecting component dimensions.

Coatings reduce surface friction and wear, allowing components to move smoothly. This lowers energy losses and improves overall system efficiency.

Yes, PVD coatings act as a protective barrier that helps resist corrosion caused by chemicals, moisture, and aggressive operating environments.

Yes, PVD coatings are commonly applied during refurbishment to restore surface performance and extend the life of worn components.

Industries such as oil and gas, chemical processing, power generation, water treatment, HVAC, and pharmaceuticals benefit greatly from coated pump and compressor components.

Comments are closed