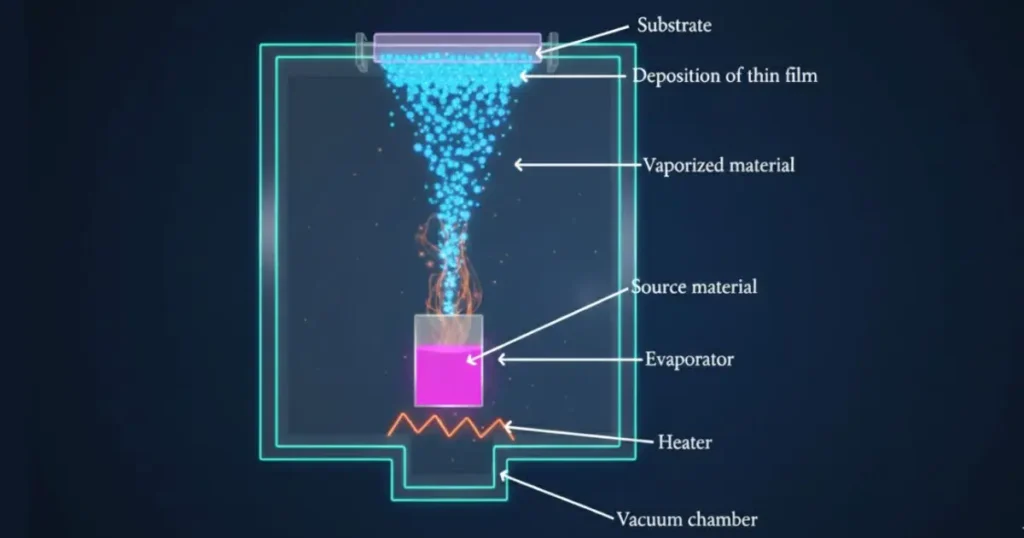

PVD (Physical Vapor Deposition) technology represents a significant leap in surface engineering. To understand what is PVD coating, one must look at this sophisticated vacuum-based process where solid source materials are transformed into a vapor state and then condensed onto a target component. This creates a high-performance, atomic-level bond that results in a coating layer typically between 1 and 5 microns thick—roughly 1/50th the thickness of a human hair, yet harder than steel.

It’s not just about making things tougher; it’s about fundamentally transforming the surface properties to significantly extend tool life, boost performance, and even enhance aesthetics. If you’re looking for a reliable pvd coating service in India, understanding this technology is your first step toward unlocking superior operational efficiency. Arka PVD Coating stands as one of the leading pvd coating manufacturers in India, committed to delivering cutting-edge PVD coating solutions that redefine durability.

Technical Specifications: The Science of Durability

To understand why PVD is superior, we must look at the technical data. Unlike standard coatings, PVD offers extreme hardness and thermal stability.

| Coatings | Arka TiN | Arka TiAlN | Arka AlCrON | Arka TiSiN | Arka AlTiFor | Arka Tasc |

| Hardness | 23 | 32 to 35 | 33 to 36 | 35 to 40 | 34 | 33 |

| Thickness (microns) | 1 to 4 µm | 2 to 4 µm | 2 to 5 µm | 1 to 4 µm | 2 to 8 µm | 4 to 8 µm |

| Friction Coefficient | 0.5 | 0.5 | 0.5 | 0.4 | 0.35 | 0.35 |

| Color | Gold | Purple Black | Grey | Copper | Violet Grey | Grey |

| Max Service Temperature | 600 °C | 900 °C | 1000 °C | 1100 °C | 900 °C | 900 °C |

| Process Temperature | 200-400 °C | 400-500 °C | 400-500 °C | 400-500 °C | 400-500 °C | 450 °C |

The PVD Coating Process: Breaking Down the Science

So, what exactly is Physical Vapor Deposition (PVD)? In simple terms, it’s a high-tech process that applies a super-thin, yet incredibly hard and protective, layer onto a material. Imagine taking a solid material, turning it into a gas, and then letting that gas settle back down as a new, stronger layer on your part—all at an atomic level. This creates a bond so strong, it becomes an integral part of the tool’s surface.

Let’s look at the three main steps that make physical vapor deposition (pvd) such an effective process:

1. Preparation: The Foundation of Quality

Before any coating happens, the part needs meticulous preparation. This isn’t just a quick wipe-down; it’s a crucial stage involving deep cleaning and often specialized polishing. Any oil, dust, or microscopic impurity on the surface can prevent the PVD film from bonding correctly, leading to a weaker coating. At Arka PVD Coating, we ensure your components are perfectly clean and ready to receive their protective layer.

2. Deposition: The Heart of the PVD Process

The heart of the Arka PVD process involves Cathodic Arc Evaporation. Inside a high–vacuum chamber, a high-current, low-voltage arc is struck on the surface of a metal target (like Titanium). This arc blasts away metal atoms, ionizing them into a dense plasma. These ions are then accelerated toward the negatively charged tools or parts at high velocity. When they strike the surface, they form a dense, structural lattice that is physically integrated into the substrate, rather than just sitting on top of it.

3. Post-Treatment & Inspection

After completing the deposition process, we carefully cool the components before subjecting every part to a rigorous quality inspection. This final phase verifies that the PVD layer reaches the required thickness and maintains an flawless finish. By eliminating even minor defects at this stage, we guarantee that every component delivers peak performance in its specific industrial application.

Read More

Difference between PVD and Powder Coating?

PVD vs. CVD – Which One Is Right for You?

While both Physical Vapor Deposition (PVD) and Chemical Vapor Deposition (CVD) utilize high-vacuum environments for surface treatment, each process alters the substrate material in fundamentally different ways.

| Feature | PVD Coating | CVD Coating |

| Process Temperature | 400°C-600°C (Low) | ~1000°C (High) |

| Thickness | 1-5 Microns (Ultra-thin) | 25-75 Microns (Thicker) |

| Edge Sharpness | Maintain Razor Edges | May Round Sharp Edges |

| Eco-Friendly | Yes; REACH and RoHS compliant | No; contains Hexavalent Chromium |

Substrate Compatibility – What Materials Can We Coat?

At Arka PVD, we specialize in coating a wide variety of substrates to ensure maximum performance:

- High-Speed Steel (HSS): Ideal for PVD because the process temperature stays below the tempering point of the steel.

- Tungsten Carbide: Common for cutting inserts; PVD enhances its heat resistance for higher cutting speeds.

- Tool Steels (D2, H13, M2): Highly effective for dies and molds, preventing galling and sticking.

- Stainless Steel: Often coated for functional wear resistance or aesthetic finishes like gold or bronze.

- Titanium Alloys: Frequently used in aerospace and medical implants for a biocompatible, low-friction surface.

Comparison: PVD vs. Conventional Finishes (The Quality Choice)

| Feature | PVD Coating | Powder Coating | Electroplating |

| Thickness | 1–5 µm (Ultra-thin) | 50–250 µm (Thick) | 5–50 µm (Medium) |

| Durability | Extremely High | Moderate | Low to Moderate |

| Precision | Retains Sharp Edges | Rounds Off Edges | Can Alter Dimensions |

| Eco-Friendly | Yes (Zero Waste) | Moderate | No (Chemical Baths) |

Why PVD is Essential for Modern Industry

The PVD process delivers unique performance advantages that other coating methods simply cannot match. Because of this superior durability and precision, PVD technology now serves as an indispensable standard across a wide range of global industries.

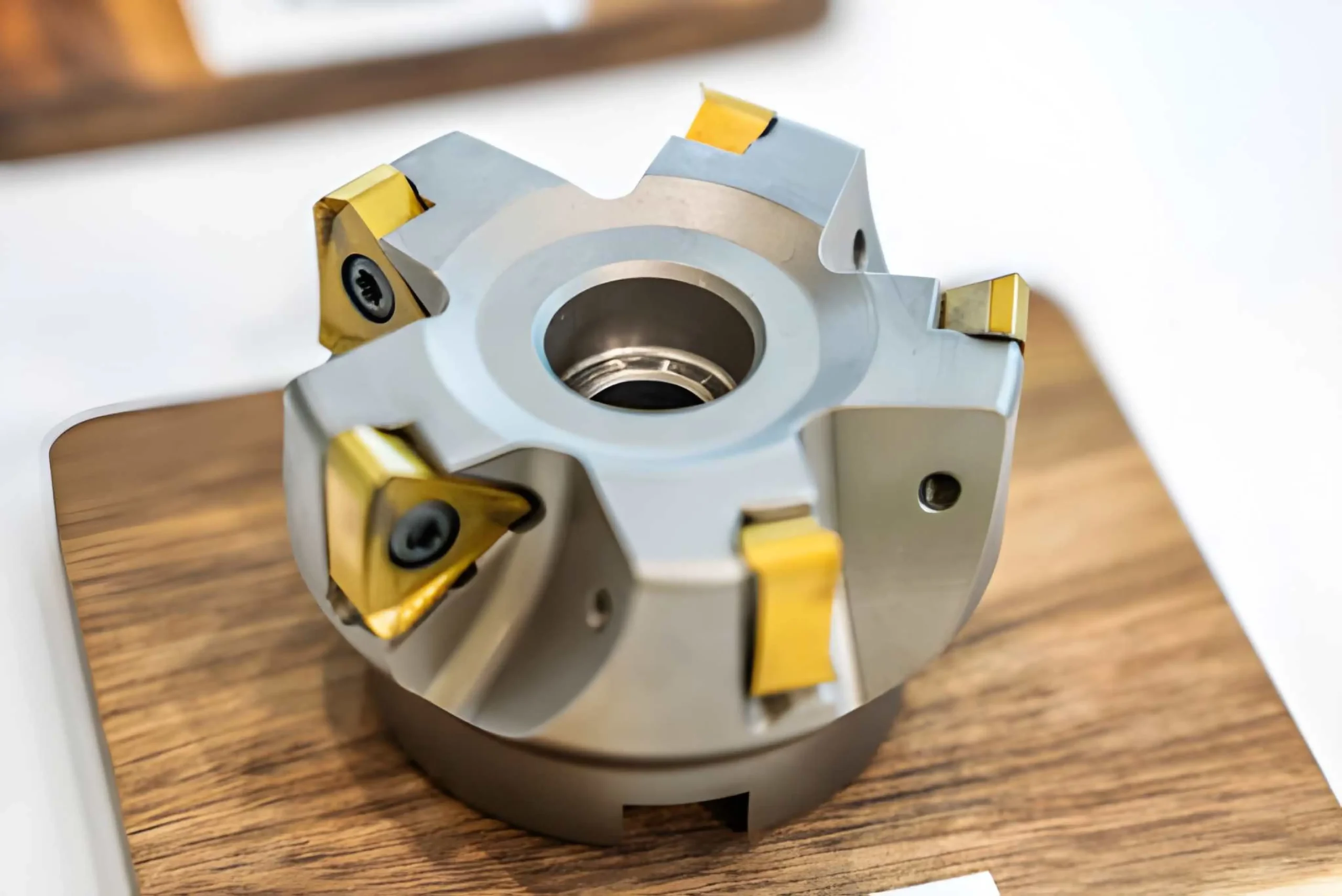

The Unbeatable Advantages of Hard Coating for Industrial Tools

Superior Durability & Extended Tool Life

PVD coatings create an extremely hard coating for industrial tools. This incredible hardness, often several times greater than the base material, dramatically increases the tool’s resistance to wear. The result? A significant tool life extension coating, meaning fewer replacements, less downtime, and substantial cost savings.

Reduced Friction, Enhanced Performance

Many PVD coatings inherently offer low friction nano coatings. This is critical for moving parts, cutting tools, and molds, where reduced friction means less heat generation, smoother operation, and improved efficiency. For example, in coating for gear cutting, low friction ensures smoother meshing and reduced energy loss.

Exceptional Heat & Oxidation Resistance

Industrial applications often involve high temperatures. PVD films provide outstanding high temperature PVD coating capabilities, protecting tools from softening or degrading. Coupled with excellent oxidation resistance coatings, this means your components can perform reliably in extreme environments without succumbing to thermal breakdown or corrosion.

Precision and Aesthetic Versatility

Unlike thicker coatings, PVD forms an extremely thin film (typically 1-5 microns). This means it doesn’t alter the dimensions of precision parts, making it ideal for tight tolerance applications. Beyond function, PVD also offers striking aesthetic finishes like the classic gold pvd coating or the sleek pvd bronze coating, adding value to luxury items.

Protection Against Erosion

In abrasive environments, parts can suffer from material loss due to constant impact. Erosion protection PVD coating creates a tough barrier that shields the underlying substrate from premature wear.

Decision Guide: Which PVD Coating Do You Need?

At Arka PVD Coating, we understand that one size doesn’t fit all. That’s why we offer a range of specialized PVD coating solutions, each engineered to address specific industrial challenges and deliver maximum performance. As a leading pvd coating manufacturer and pvd coating factory in India, we pride ourselves on our advanced offerings.

Choosing the Right PVD Coating: ARKA’s Specialized Range

ARKA TIN (Titanium Nitride Coating)

The Versatile Workhorse our titanium nitride coating (tin pvd coating) is a foundational choice known for its incredible hardness, wear resistance, and distinctive gold coating appearance. It’s a go-to for general-purpose applications, significantly improving the lifespan of drills, milling inserts, and punches. Its titanium coating biocompatibility also makes TiN PVD coating suitable for certain titanium nitride coating medical devices. Many TIN coated HSS tools benefit immensely from this layer.

ARKA ALCRON (Aluminum Chromium Nitride Coating)

For Extreme Conditions when the heat is on, ARKA ALCRON (aluminum chromium nitride coating) steps up. This advanced coating offers exceptional wear and heat resistance, making it perfect for high-speed machining coating and working with tough, abrasive materials. It’s often chosen for applications requiring a durable Chrome finish coating or Steel finish coating due to its robust nature. As one of the premier alcrn pvd coating services in India, we ensure top performance.

ARKA TALIN (Aluminum Titanium Nitride Coating)

The Oxidation Defender ARKA TALIN (aluminium titanium nitride coating) is specifically engineered for high-temperature applications where oxidation resistance is paramount. It excels in coating for wet & dry machining and is particularly effective as altin coating for cutting aluminum and altin coating for stainless steel, preventing material build-up and ensuring clean cuts. It’s also an excellent high temperature PVD coating.

ARKA ALTIFOR

For Robust Forming Operations our ALTIFOR PVD coating services are specifically formulated for PVD coating for steel forming tools. It’s a gallling resistant coating that dramatically extends the life of Press tools and dies used with high-strength steels, preventing material adhesion and reducing friction. This is an ideal Coating for Form Tools.

ARKA TISIN

Conquering Hard Materials the ARKA TISIN nano composite coating is designed for the toughest jobs, offering superior hardness and low friction when machining extremely hard materials (over 50 HRC). It’s a high-performance nano coating technology that stands out.

Industrial Applications of PVD Coatings: From Cutting Tools to Aerospace

The versatility of PVD coatings means they are critical across a vast range of industrial sectors. From small, intricate parts to large, heavy-duty components, the benefits are clear. Arka PVD Coating is proud to be one of the pvd coating service providers in India, offering solutions for:

- Cutting Tools: Enhancing drills, mills, reamers, and particularly providing robust Carbide cutting tools coating for superior performance and longevity.

- Dies & Molds: Extending the life of coating for die casting molds and PVD coating for forging dies, preventing wear, galling, and sticking.

- Automotive & Aerospace: Critical for engine components, landing gear, and precision parts where reliability and performance are non-negotiable, acting as a vital coating for aerospace & medical tools.

- Medical Instruments: Offering titanium nitride coating medical devices and other biocompatible solutions for surgical tools and implants.

- General Engineering: Providing solutions like coating for cast iron & steel parts and other functional components that need enhanced durability.

Why PVD is the “Green” Choice for India

PVD coating is an environmentally friendly “dry” process. Unlike traditional methods, it involves no hazardous chemical baths and produces no toxic wastewater, helping Indian manufacturers meet global sustainability standards.

Conclusion

Understanding “What is PVD Coating?” reveals a world of advanced material science designed to overcome the limitations of traditional materials. It’s not just a layer; it’s an investment in increased productivity, reduced costs, and superior product performance.

As you seek to optimize your industrial processes, choosing the right partner for your PVD coating service is paramount. Arka PVD Coating is dedicated to being the Best pvd coating service provider in india, offering not just coatings, but comprehensive solutions backed by expertise and a commitment to quality. Whether you need specific titanium nitride coating or a tailored alcrn pvd coating solution, our team is ready to assist.

Don’t let wear and friction limit your potential. Contact Arka PVD Coating today to discover how our expertise can transform your tools and components. Get in touch for a consultation or to discuss your specific pvd coating requirements.

FAQs about pvd coating

PVD coating is an ultra-thin (1–5 µm) metallic film applied in a vacuum primarily for functional performance (hardness, friction). Powder coating is a much thicker (50–250 µm) polymer-based layer applied for cosmetic finish and basic corrosion resistance.

Since the PVD process creates a bond at the molecular level, these coatings effectively resist chipping, cracking, or peeling during standard industrial operations. For precision cutting tools, the coating typically increases service life by 300% to 1000%, though the exact gain depends on your specific application and the material you are processing.

Yes. Unlike electroplating, PVD operates as a clean, dry, zero-emissions technology. By using a vacuum process, we eliminate hazardous chemical baths, toxic acids, and VOCs. Our treatments fully comply with international REACH and RoHS standards, offering a sustainable alternative for modern manufacturing.

You should choose PVD coating because it creates an extremely hard surface that typically increases tool life by 3 to 10 times. This reduces the frequency of replacement, leading to less downtime and significant cost savings.

While we primarily engineer PVD coatings for electrically conductive metals like steel, aluminum, and carbide, our advanced capabilities extend further. Through specialized pre-treatment techniques, we can also successfully apply high-performance PVD films to non-conductive substrates, including ceramics and engineering-grade plastics.

Arka PVD specializes in high-value industrial components like Carbide cutting tools, extrusion and forging dies, complex engine parts, and biocompatible coatings for medical instruments that require exceptional accuracy and wear resistance.

PVD coating is cost-effective because the investment is quickly recovered through significantly extended tool life and reduced maintenance. The savings from less downtime and fewer replacements easily outweigh the initial coating cost.

PVD Coating

PVD Coating

PVD Coating For Industrial Components In India | ARKA PVD

November 14, 2025 6:07 am[…] What is PVD Coating? […]

The 4-Step PVD Coating Process | Arka PVDCoating

December 16, 2025 9:48 am[…] Read more: What is PVD Coating? […]