A Complete Guide to PVD Coating: Process, Benefits, and Industrial Applications.

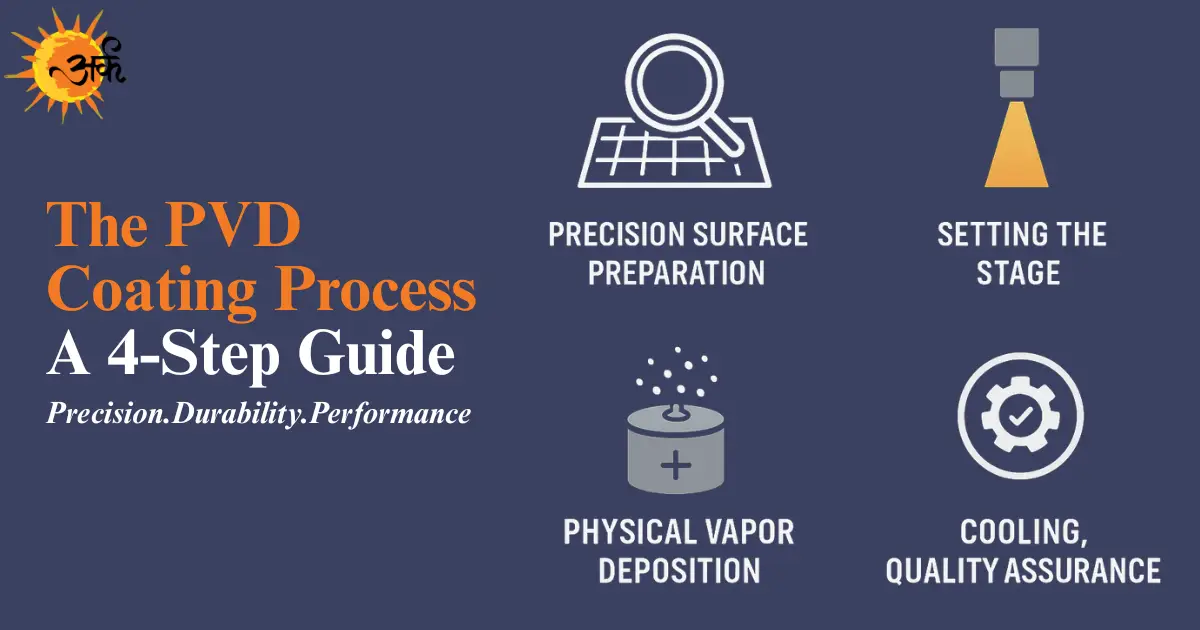

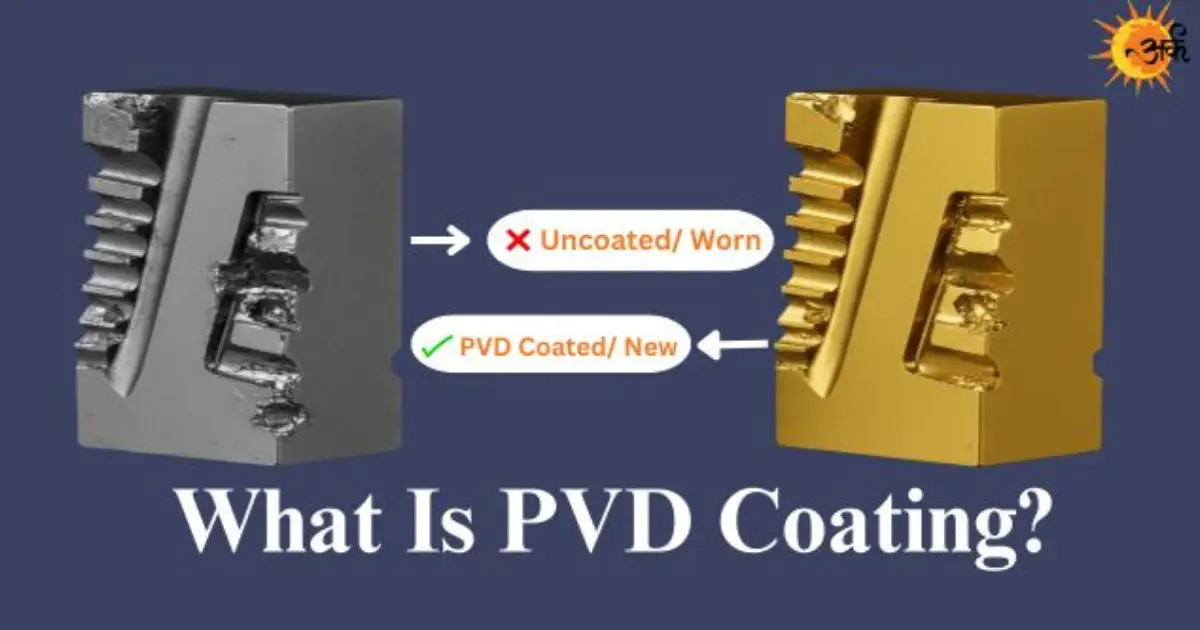

PVD (Physical Vapor Deposition) technology represents a significant leap in surface engineering. To understand what is PVD coating, one must look at this sophisticated vacuum-based process where solid source materials are transformed into a vapor state and then condensed onto

READ MORE

PVD Coating

PVD Coating