Introduction: The High Cost of Wear and Tear

Let’s be honest: in today’s fast-paced manufacturing world, nothing is more frustrating than unexpected equipment failure. The moment a critical mold surface wears down, or a cutting tool dulls prematurely, your entire operation stops. You lose time, you lose material, and consequently, you lose money. We know this pain point well. We understand that what you truly need is not just a tool, but an asset you can trust to perform day after day.

The foundation of that trust lies in advanced surface technology. Specifically, a remarkable process called Physical Vapor Deposition (PVD).

The PVD coating process isn’t some black box magic; it’s a rigorous, scientific methodology that creates a molecular shield over your parts. At Arka PVD Coating, we’ve mastered this process, turning standard industrial components into truly high-performance workhorses. We want to explain this critical technology for you. This guide will walk you through the precise four-stage journey we use—a journey that ensures quality, durability, and a competitive edge for your business.

What exactly is PVD? Think Molecular Armor

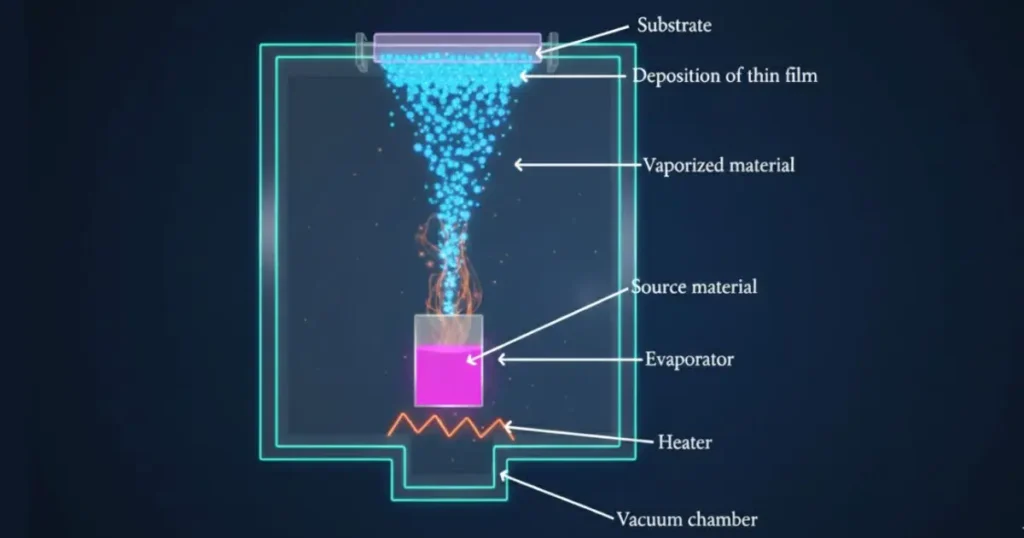

Before we dive into our procedure, let’s simplify the science. What are we actually doing?

Essentially, PVD coating involves taking a solid material—like titanium, chromium, or carbon—and turning it into a vapor inside an airless environment. We then direct those vaporized atoms to settle and bond onto your component’s surface.

The result is an ultra-thin film, often thinner than a few microns. Despite its minimal size, this layer delivers colossal benefits. This “molecular armor” is what gives your parts:

- Extreme, Lasting Hardness: It provides a protective surface far tougher than the component’s base metal.

- Significantly Reduced Friction: This means less heat, less energy waste, and smoother operation.

- Superior Resistance to Abrasive Wear: It drastically extends the operational life of expensive tools.

- Defense Against Corrosion: It provides a necessary barrier against harsh chemicals and environments.

The strength and adhesion of this coating, however, depends entirely on the methodical execution of the four essential stages of the PVD coating process. For businesses seeking reliable partners, understanding this process is crucial when evaluating PVD coating companies in India.

Our 4-Stage Protocol: Engineering Reliability

At Arka PVD Coating, we don’t treat any step lightly. Every phase is a commitment to quality that translates directly into the reliability of your finished product.

1. Stage One: The Non-Negotiable Start – Precision Surface Preparation

We can’t stress this enough: A perfect coating demands a perfect surface. If the component isn’t flawlessly clean, the coating will inevitably fail prematurely. Any contaminants—such as residual cooling oils, tiny dust particles, or fingerprints—will act as a weak point, preventing the coating from achieving that critical molecular bond.

The Triple-Check Cleaning Method:

- Initial Review: Every item is first visually inspected for gross contamination or physical damage before any washing begins.

- The Power of Ultrasonics: We utilize specialized ultrasonic cleaning tanks. These chambers use high-frequency sound waves to create minute scrubbing bubbles throughout the solution. This method literally shakes off contaminants, reaching into the smallest pores and deepest channels that simply cannot be cleaned manually.

- Multi-Stage Rinsing: Following the powerful cleaning agents, multiple pure water rinses are used to ensure absolutely no chemical residue remains. The parts are then carefully dried in a controlled, heated environment to prevent any trace of moisture.

- Final Pre-Inspection: Our technicians then perform a final verification, confirming the parts are at the demanding standard of molecular cleanliness. This rigorous approach is the single biggest predictor of long-term coating success, which is why we offer a superior PVD coating service in India.

2. Stage Two: Setting the Stage – Fixturing and Achieving Deep Vacuum

Once the surface preparation is complete, we prepare the environment for the atomic-level transformation.

Expert Fixturing:

- We do not just toss the components into the chamber; we mount them onto custom fixtures. This requires technical know-how because we must consider every angle.

- Proper fixturing ensures that the coating source has a clear line of sight to all critical surfaces, which is key to achieving consistent thickness and uniform coverage across every part in the batch.

- Once we fix them, we carefully load the racks into the large, high-specification coating chamber.

Creating the Perfect Void:

- We seal the chamber, and the pumping process begins. This is an extended, meticulous phase where powerful vacuum pumps remove nearly all the atmospheric air, driving the pressure down to a high vacuum—a state far more empty than the vacuum found in space.

- Why the deep vacuum? If air molecules remained, they would collide with the coating atoms during deposition, causing them to bounce away. The high vacuum ensures that the coating atoms travel cleanly from the source to your component, resulting in a purer, denser, and stronger film.

Thermal and Electrical Preparation:

- Often, we pre-heat the components to a specific temperature. This thermal preparation is necessary to help the coating atoms bond effectively upon impact.

- In some cases, we perform a final cleaning step known as Plasma Etching inside the chamber. This uses an energetic stream of plasma to atomize and remove any last trace of oxidation, leaving the surface perfectly activated and ready to receive the coating.

3. Stage Three: The Heart of the Matter – Physical Vapor Deposition (The Transformation)

This is the central process where the molecular armor is built.

Inside the controlled vacuum, the solid coating material (the target) is turned into a cloud of plasma. We employ advanced methods to achieve this:

- Cathodic Arc Vaporization: We pass an extremely high electrical current through the target material. This creates a powerful electrical arc that instantly vaporizes the solid material, releasing a cloud of highly energetic, charged particles (plasma). This method is exceptional for producing the densest and hardest coatings, such as those required for high-stress applications like Cutting Tools. For standard abrasion resistance, we often use our proven TiN PVD coating (Titanium Nitride).

- The Critical Reaction: At this point, we strategically introduce a reactive gas, such as Nitrogen or Carbon, into the chamber. This gas immediately bonds with the metal vapor ions in the plasma. For advanced, heat-intensive applications, we move beyond TiN, utilizing Aluminum and Chromium targets combined with nitrogen to synthesize robust AlCrN coatings (Aluminum Chromium Nitride), which are perfect for high-speed, high-temperature operations.

- The Bond: A controlled electrical bias (a negative charge) is applied to the components being coated. Because the plasma atoms are positively charged, this bias dramatically pulls them towards the surface. They don’t just float down; they are accelerated and forced to bond, ensuring phenomenal adhesion at the atomic level.

- Precision Control: Our technicians continuously monitor and adjust temperatures, pressure, and gas flow for hours. This meticulous control is the only way to guarantee the required thickness—typically between 1 to 5 microns—is perfectly uniform across the entire batch.

Read more: What is PVD Coating?

4. Stage Four: Final Confirmation – Cooling, Quality Assurance, and Release

The coating application is finished, but the job is not complete until we have certified the quality.

Cooling and De-Fixturing:

- The chamber temperature is gradually and carefully reduced. This controlled cooling cycle is vital. Rapid cooling could introduce thermal stresses or micro-cracks in the newly formed coating layer, completely compromising its effectiveness.

- Once safely cooled, the parts are removed from the fixtures.

The Final Proof: Rigorous Quality Control (QC):

This is where we back up our promises. Every batch undergoes extensive testing before shipment:

- Adhesion Testing: We use industry-standard tests to physically challenge the strength of the bond between the coating and the base material.

- Thickness Verification: Highly precise instruments verify that the coating thickness is exactly within the required tolerance and is uniform across the entire component.

- Visual and Performance Inspection: Each part is visually checked for consistency, ensuring the coating finish is flawless and meets our ISO-certified standards.

Only after receiving a full stamp of approval are the parts packaged securely and shipped out, ready to be put to work in your facility, backed by the confidence of a certified process.

Conclusion: Partnering for Reliable Durability

The meticulously executed PVD coating process is more than just a service—it’s an investment in your company’s uptime and profitability. Our dedication to perfection is why our coatings, from standard TiN PVD coating to advanced AlCrN coating, deliver such superior results, especially when applied to demanding assets like Cutting Tools.

When looking at the wide range of PVD coating companies in India, remember that expertise and process control are the defining factors for coating success. We believe our systematic approach to the PVD process makes us a leading choice for any organization requiring exceptional performance.

We are your trusted partner, ready to help you extend the life of your critical assets and transform your operational efficiency through our top-tier PVD coating service in India.

Ready to gain the competitive edge that comes with superior component durability?

Contact the PVD experts at Arka PVD Coating today for a free consultation and customized coating recommendation.

PVD Coating

PVD Coating

Comments are closed