- +91 94268 85636

- Mon to Sat: 9.00 am - 6.00 pm

Titanium Nitride (TiN) coating is one of the most widely used PVD (Physical Vapor Deposition) coatings in the world, known for its hardness, golden finish, and excellent wear resistance. At ARKA PVD Coating, we specialize in delivering advanced TiN PVD coating services in Gujarat and across India helping industries enhance the life, performance, and durability of their tools and components.

We deliver cost-effective and high-quality coating solutions to manufacturers across India. TiN coating is a universal solution for top performance. It helps you protect your investment and make sure your operations function smoothly and at a low cost.

Our detailed technical specifications clearly outline the key benefits, such as extended operational life and reduced downtime.

Call Us

Client Satisfaction

Titanium Nitride (TiN) is a thin, gold-colored PVD coating applied to tools and components to increase hardness, reduce friction, and protect against heat. It not only improves performance but also adds a premium finish that makes tools last up to 3x longer.TiN PVD coating is widely used for extrusion tooling and plastic extrusion dies where high surface hardness, reduced material build-up and extended die life are critical.

Experience(Years)

Advanced Coating Solutions

Commitment to Quality

Client Satisfaction Rating

Shrihari Industrial estate, Village Sarangpur, GIDC Ankleshwar Bharuch 393001

A variety of industries, from general manufacturing to more niche ones like aerospace and medicine, can benefit from ARKA PVDCoating's PVD coating services. To understand the engineering standards and technical benefits of PVD technology, read our 2026 PVD Industry Guide.

We offer PVD coating for cutting tools that makes them last much longer and work better. We put our coatings on a lot of different equipment, such drills, end mills, reamers, taps, and saws. Our TiN coating for cutting tools is ideal for both HSS and carbide tools.

Read More

We are experts in PVD coating for extrusion dies and PVD coated molds. Our coatings work great for die casting tools and plastic molding applications, like cavities, cores, and ejector pins. Our remedies make things less likely to wear out and stop galling.

Read More

We are one of the best companies that offers automotive PVD coating services. We put long-lasting, wear-resistant coatings on a lot of different parts, such as engine parts like pistons and gears. We also cover sections of the transmission, fasteners, and fuel system injectors.

Read More

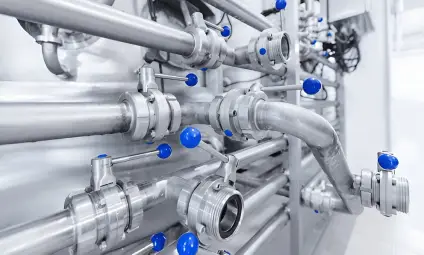

We offer industrial coatings for the energy sector, such as pvd coating for parts used in oil and gas and power generation. Our products make drilling equipment, pumps, and valves last longer in very harsh conditions.

Read MoreThe titanium nitride PVD coating process puts a very thin, very hard layer of TiN on the surface of a tool. This hard coating for industrial tools increases the surface's wear resistance and lowers its friction coefficient. The coating makes it harder to scratch and heat up by creating a strong barrier. This enhanced protection results in significant tool life improvement with TiN, which lets them cut and feed faster while still working at their best.

Compared to uncoated tools, TiN-coated drills and cutters can last up to 4 times longer, reducing downtime and replacement costs.

We understand your tool requirements and recommend the right Titanium Nitride (TiN) coating for maximum wear resistance and durability.

With advanced PVD coating machines, we ensure uniform TiN coating for cutting tools and molds that enhances performance and tool life.

From Ahmedabad to Surat, Vadodara to Rajkot, we deliver TiN-coated tools across Gujarat & India—on time, within budget.

ARKA PVD Coating is Gujarat’s trusted name in surface solutions. We are the best place to get high-end PVD coating solutions for industrial tools.

10+ years of experience in PVD technology

Advanced PVD machines delivering consistent results

ISO-certified quality standards

Gujarat-based facility serving PAN India

Trusted by industries in Ahmedabad, Vadodara, Rajkot, Surat, Bharuch, Ankleshwar, and beyond. When you choose ARKA, you are choosing enhanced tool life, improved performance, and reliable production for your critical components.

Our experts recommend TiN coating for applications where durability and appearance both matter, making it one of the most cost-effective surface treatments available.

| Characteristic | Value |

| Color | Gold |

| Nano Hardness (GPa) | 23 |

| Friction Coefficient | 0.5 |

| Coating Thickness | 1 to 4 µm |

| Max Service Temperature | 600 °C |

| Process Temperature | 200–400 °C |

Here are some answers to common questions about our services. With our advanced processes and commitment to quality, you can be confident that your tin coating are in expert hands.

PVD coating is a modern way to treat surfaces that makes many things work better, last longer, and look better. It is used to make parts in the automotive, aerospace, and medical fields harder, more resistant to corrosion, and better overall

Depending on how and where it is utilized, a PVD coating can last for different amounts of time. These coatings, on the other hand, are made to last a long time and are known to greatly enhance the life of tools and parts.

While the initial PVD coating cost is usually more than that of certain older technologies, but the long-term benefits make it a very good investment. Over time, the longer tool life, less downtime, and better performance add up to big savings.

PVD coating is a thin, hard, metallic layer that is put on in a vacuum. It is mostly utilized for functional performance. Powder coating is a thicker layer made of polymers that is applied as a dry powder and cured with heat. It is mostly used for cosmetic finishes and to protect against rust.

ARKA PVD Coating provides services to industries across Pan India.We have a strong presence in Gujarat, where we serve industrial cities like Ahmedabad, Vadodara, Rajkot, and Surat. We also supply all coated equipment and parts across the country.