- +91 94268 85636

- Mon to Sat: 9.00 am - 6.00 pm

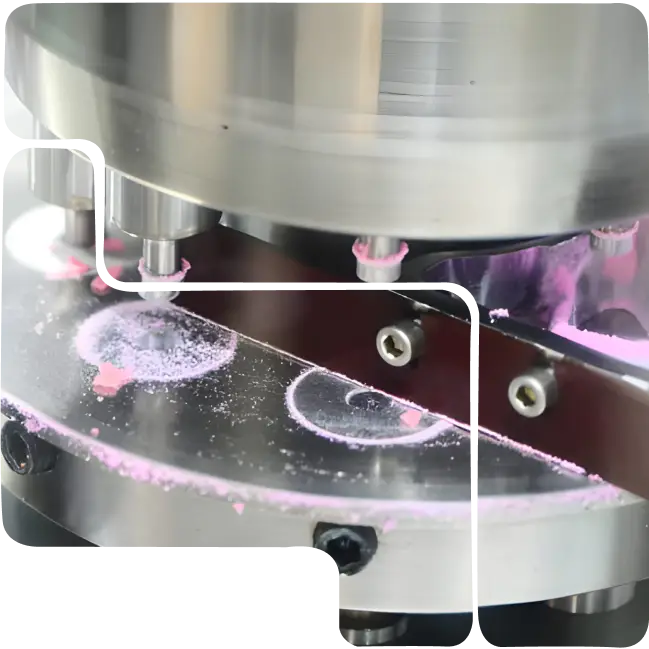

At ARKA PVD, we provide high-quality PVD coating services for medical instruments across India, designed to deliver unmatched durability, safety, and precision. Our Physical Vapor Deposition (PVD) coating creates a thin, biocompatible hard layer that enhances wear resistance, corrosion protection, and sharpness retention for surgical tools and implants. Arka also provides PVD coating for tablet punching tools, ensuring superior abrasion protection from hard particles and reduced pick-up of material onto the punch tips. Perfect for scalpels, forceps, dental tools, and orthopedic devices, this coating extends instrument life, ensures hygienic performance, and reduces replacement costs. For healthcare providers seeking efficiency, safety, and reliability, our PVD coatings solution are the ideal.

Call Us

Client Satisfaction

PVD coating for medical instruments offers unmatched durability, precision, and safety. By adding a protective layer, it ensures surgical tools and devices last longer, resist wear, and perform with consistency—critical in healthcare environments.

PVD coatings shield instruments from corrosion, wear, and sterilization damage, extending their reliability in surgical use.

The coating enhances hardness and reduces surface friction, keeping surgical scissors, forceps, and medical drills sharp and precise for longer.

Fewer replacements and longer-lasting instruments help reduce hospital and clinic expenses, ensuring cost-efficient operations.

Our wear-resistant coatings ensure smoother operations, consistent results, and compliance with strict medical standards.

Trusted by industries in Ahmedabad, Vadodara, Rajkot, Surat, Bharuch, Ankleshwar, and beyond. When you choose ARKA, you are choosing enhanced tool life, improved performance, and reliable production for your critical components.

Our PVD coatings for medical instruments deliver superior wear resistance, corrosion protection, and extended tool life—ensuring reliability and precision in critical medical applications.

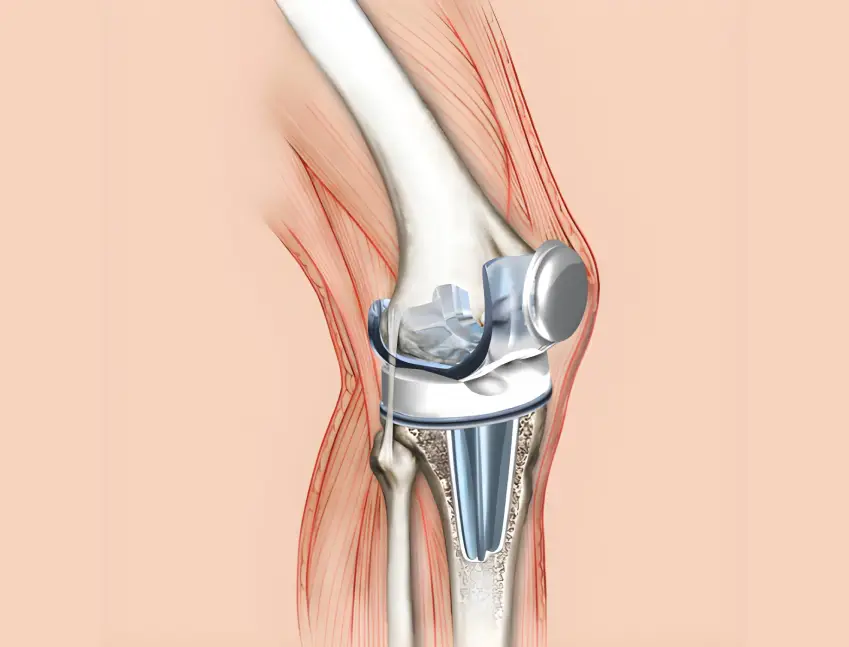

Our advanced PVD coatings boost implant longevity & biocompatibility for knee/hip replacements, ensuring patient safety and better device performance.

Experience smoother handling and longer-lasting performance with coated forceps and clamps, reducing wear and ensuring consistent grip.

Our PVD-coated medical drills and reamers provide enhanced friction control and chip removal, delivering cleaner cuts and improved longevity.

Coated endoscopic and laparoscopic instruments offer superior abrasion and corrosion resistance, maintaining precision in minimally invasive procedures.

Coated scissors and needle holders ensure smooth operation, reduced torque, and longer-lasting cutting edges for reliable surgical performance.

Whether HSS or carbide instruments, our PVD coatings boost hardness, reliability, and hygiene—ideal for demanding surgical and diagnostic applications.

At ARKA, we are recognized as a trusted partner for PVD coating solutions for medical instruments.

Call Us

Our diverse range of specialized coatings is designed to meet needs, ensuring optimal performance for our clients. We offer a wide range of specialized coatings for specific uses, perfect for various medical instruments and applications. Here are some of our most popular PVD coating for medical instruments.Learn more about the PVD process here.

ARKA TIN PVD Coating

Our versatile titanium nitride tin pvd coating is known for its high hardness and low friction, making it ideal for metal-cutting and forming tools.

Read MoreARKA ALCRON PVD Coating

We offer premium alcrn pvd coating services that provide exceptional wear and heat resistance for high-speed machining and tough materials.

Read MoreARKA TALIN PVD Coating

Aluminum Titanium Nitride coating is highly resistant to both wear and oxidation, improving the performance of drills, mills, and inserts.

Read MoreARKA TISIN PVD Coating

Nano composite coating is designed for machining extremely hard materials (over 50 HRC), offering excellent sticking power and low friction for high-speed applications.

Read MoreARKA ALTIFOR PVD Coating

ALTIFOR PVD coating services are perfect for extending the life of forming tools used with high-strength steel, preventing galling and wear.

Read MoreARKA TASC PVD Coating

The TASC PVD Coating is a multi-functional solution designed to increase long-term cost-effectiveness and productivity, making it an excellent investment.

Read MoreDLC PVD Coating

The DLC PVD coating service creates a very hard, carbon-based film with exceptional properties, including very low friction and high hardness.

Read MoreHere are some answers to common questions about our services. With our advanced processes and commitment to quality, you can be confident that your medical instruments are in expert hands.

PVD coating for medical instruments enhances hardness, corrosion resistance, and durability. It ensures instruments maintain precision and long-term performance in surgical and clinical applications.

PVD coating on medical tools lasts several times longer than uncoated instruments. It protects against wear, sterilization processes, and chemical exposure, ensuring reliable performance.

The benefits include increased hardness, reduced friction, and superior corrosion resistance. PVD coating maintains precision, reduces maintenance, and extends the life of surgical and diagnostic instruments.

PVD coating is widely applied on scalpels, surgical blades, orthopedic tools, and endoscopic instruments. It enhances durability, precision, and safety for medical procedures.

ARKA PVD Coating provides advanced surface solutions for medical instruments. Our coatings deliver unmatched hardness, precision, and reliability for long-lasting performance in healthcare settings.