- +91 94268 85636

- Mon to Sat: 9.00 am - 6.00 pm

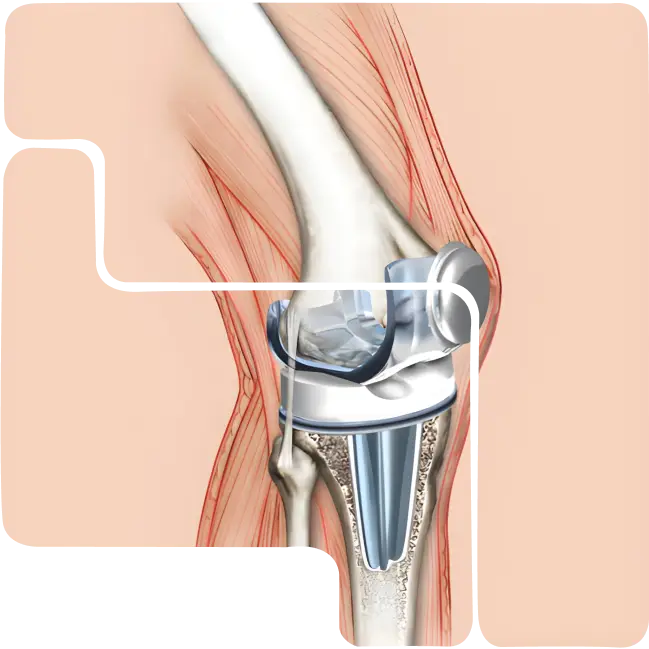

In high-demand industries like die casting, hot forging, and metal injection molding (MIM), tools face extreme stress, high heat, and rapid wear. To overcome these challenges, TASC (Multi-Functional) PVD Coating in India provides unmatched hardness, superior resistance to soldering, and enhanced durability. This advanced protection also extends to critical medical applications, significantly improving the longevity and performance of implants.

At ARKA PVD Coating, Gujarat, we specialize in TASC coatings that significantly extend tool life, reduce maintenance costs, and improve efficiency. Serving leading industrial hubs like Ahmedabad, Vadodara, Rajkot, Surat, Ankleshwar, and Bharuch, our multi-functional coating services are trusted by industries across India.

Our detailed technical specifications clearly outline the key benefits, such as extended operational life and reduced downtime.Call Us 24/7

Client Satisfaction

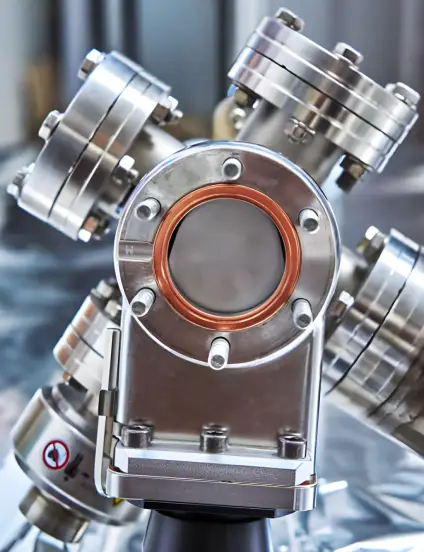

TASC coating is a multi-functional PVD (Physical Vapor Deposition) coating designed for applications where tools and components face repeated exposure to heat, pressure, and molten metals. Unlike conventional coatings, It is engineered for extreme hardness, anti-soldering performance, and erosion resistance, making it ideal for die casting, hot forging, and MIM applications.

Experience(Years)

Advanced Coating Solutions

Commitment to Quality

Client Satisfaction Rating

Shrihari Industrial estate, Village Sarangpur, GIDC Ankleshwar Bharuch 393001

These high-performance properties result from specialized vacuum engineering. Learn more about the PVD process here.

A variety of industries, from general manufacturing to more niche ones like aerospace and medicine, can benefit from ARKA PVDCoating's PVD coating services.

We offer PVD coating for cutting tools that makes them last much longer and work better. We put our coatings on a lot of different equipment, such drills, end mills, reamers, taps, and saws. Our TiN coating for cutting tools is ideal for both HSS and carbide tools.

Read More

We are experts in PVD coating for extrusion dies and PVD coated molds. Our coatings work great for die casting tools and plastic molding applications, like cavities, cores, and ejector pins. Our remedies make things less likely to wear out and stop galling.

Read More

We are one of the best companies that offers automotive PVD coating services. We put long-lasting, wear-resistant coatings on a lot of different parts, such as engine parts like pistons and gears. We also cover sections of the transmission, fasteners, and fuel system injectors.

Read More

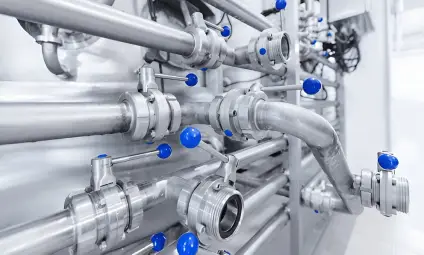

We offer industrial coatings for the energy sector, such as pvd coating for parts used in oil and gas and power generation. Our products make drilling equipment, pumps, and valves last longer in very harsh conditions.

Read MoreThe TASC multi-functional PVD coating process provides a versatile, high-performance protective layer designed to deliver wear resistance, heat stability, corrosion protection, and low friction. This advanced coating is ideal for cutting tools, forming tools, and precision components where multiple challenges—such as heat, wear, and chemical attack—must be addressed simultaneously.

Compared to uncoated tools, TASC-coated drills, dies, and inserts show longer lifespan, reduced downtime, and improved efficiency, making it one of the most adaptable solutions for modern industries.

Compared to uncoated tools, TiN-coated drills and cutters can last up to 4 times longer, reducing downtime and replacement costs.

We study your unique tool requirements and recommend TASC coating solutions designed to perform across multiple applications.

Using advanced PVD methods, we apply multi-layer TASC coatings with precision, ensuring reliable performance in demanding environments.

We provide professional and on-time TASC coating services, ensuring your tools and components achieve consistent, long-lasting results.

ARKA PVD Coating is Gujarat’s trusted name in surface solutions. We are the best place to get high-end PVD coating solutions for industrial tools.

10+ years of experience in PVD technology

Advanced PVD machines delivering consistent results

ISO-certified quality standards

Gujarat-based facility serving PAN India

Trusted by industries in Ahmedabad, Vadodara, Rajkot, Surat, Bharuch, Ankleshwar, and beyond. When you choose ARKA, you are choosing enhanced tool life, improved performance, and reliable production for your critical components.

Our experts recommend TASC coating for multi-purpose applications, superior surface protection, and reliable performance across industries

| Property | Specification |

| Nano Hardness(GPA) | 33 |

| Coating Thickness | 3 – 8 μm |

| Friction Coefficient | 0.35 |

| Max. Temperature Resistance | 900°C |

| Color Appearance | Grey |

| Process Temperature | 450°C |

Here are some answers to common questions about our services. With our advanced processes and commitment to quality, you can be confident that your tin ARKA TASC are in expert hands.

TASC (Thermally Advanced Surface Coating) is a high-performance PVD coating engineered to withstand extreme temperatures, erosion, and wear. It’s especially effective in industrial tooling applications such as die casting and hot forging. By forming a protective barrier, it enhances surface hardness, reduces friction, and extends the life of tools, which makes it a preferred choice for heavy-duty industries across India.

TASC coating is widely used in Indian industries such as automotive manufacturing, die casting, hot forging, MIM (Metal Injection Molding), medical and oil & gas. These sectors often involve high-temperature operations and aggressive environments, where TASC’s multi-functional properties—like anti-soldering and thermal stability—greatly improve tool reliability and production efficiency.

TASC coating significantly reduces tool wear, heat damage, and material adhesion, which in turn lowers maintenance frequency and replacement costs. Its durability ensures that tools perform longer between maintenance intervals, resulting in less downtime, improved cycle times, and better ROI for manufacturing companies.

Yes, TASC coating is specifically formulated for high-temperature environments like hot forging and die casting, where conventional coatings often fail. It provides a thermal barrier and erosion resistance that protects dies and molds, even under extreme operating conditions, making it ideal for Indian manufacturers working with non-ferrous metals and high-pressure casting.

Absolutely. ARKA offers TASC PVD coating services across all major industrial regions in India, not just Gujarat. With efficient logistics and nationwide support, we cater to clients from Pune, Chennai, Bengaluru, Delhi, Hyderabad, and more—ensuring timely delivery and consistent coating quality wherever you are located.