- +91 94268 85636

- Mon to Sat: 9.00 am - 6.00 pm

In today’s highly competitive industrial world, tool life, durability, and precision are critical. ALTIFOR (TiAl-based) PVD Coating in India is a next-generation solution designed to enhance the performance of forming, extrusion, and high-strength steel applications. At ARKA PVD Coating Gujarat, we specialize in delivering TiAl-based coatings that offer extreme hardness, superior wear resistance, and outstanding performance even in high-temperature environments. Whether you are in automotive, aerospace, oil & gas, or heavy metal forming, our ALTIFOR coating services in India ensure reliability, cost savings, and longer tool life.

Our detailed technical specifications clearly outline the key benefits, such as extended operational life and reduced downtime.Call Us

Client Satisfaction

ALTIFOR Coating is a Titanium Aluminum-based (TiAl) PVD coating engineered for tools that face high pressure, extreme heat, and heavy loads. Unlike traditional TiN or AlTiN coatings, ALTIFOR is formulated for superior galling resistance, chemical stability, and strength under extreme forming conditions.

Experience(Years)

Advanced Coating Solutions

Commitment to Quality

Client Satisfaction Rating

Shrihari Industrial estate, Village Sarangpur, GIDC Ankleshwar Bharuch 393001

These high-performance properties result from specialized vacuum engineering. Learn more about the PVD process here.

A variety of industries, from general manufacturing to more niche ones like aerospace and medicine, can benefit from ARKA PVDCoating's PVD coating services.

We offer PVD coating for cutting tools that makes them last much longer and work better. We put our coatings on a lot of different equipment, such drills, end mills, reamers, taps, and saws. Our TiN coating for cutting tools is ideal for both HSS and carbide tools.

Read More

We are experts in PVD coating for extrusion dies and PVD coated molds. Our coatings work great for die casting tools and plastic molding applications, like cavities, cores, and ejector pins. Our remedies make things less likely to wear out and stop galling.

Read More

We are one of the best companies that offers automotive PVD coating services. We put long-lasting, wear-resistant coatings on a lot of different parts, such as engine parts like pistons and gears. We also cover sections of the transmission, fasteners, and fuel system injectors.

Read More

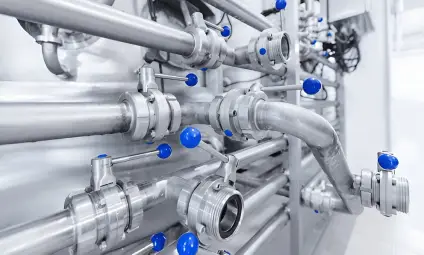

We offer industrial coatings for the energy sector, such as pvd coating for parts used in oil and gas and power generation. Our products make drilling equipment, pumps, and valves last longer in very harsh conditions.

Read MoreThe TiAl-based ALTIFOR PVD coating process forms a hard, heat-resistant, and oxidation-stable protective layer on tools and components. This advanced coating is ideal for high-speed machining, dry cutting, and applications where tools face extreme heat and wear. By reducing thermal stress and enhancing durability, ALTIFOR coating ensures consistent tool performance in demanding environments.

Compared to uncoated tools, ALTIFOR-coated drills, milling cutters, and inserts last significantly longer, lowering downtime, replacement costs, and improving cutting efficiency.

Compared to uncoated tools, TiN-coated drills and cutters can last up to 4 times longer, reducing downtime and replacement costs.

We assess your machining requirements and provide tailored ALTIFOR coating solutions designed to maximize productivity and tool life.

Using advanced PVD technology, we apply TiAl-based ALTIFOR coatings with high accuracy, ensuring superior heat resistance, wear protection, and durability.

We deliver professional and timely ALTIFOR coating services, ensuring your coated tools are reliable, cost-effective, and ready to perform.

ARKA PVD Coating is Gujarat’s trusted name in surface solutions. We are the best place to get high-end PVD coating solutions for industrial tools.

10+ years of experience in PVD technology

Advanced PVD machines delivering consistent results

ISO-certified quality standards

Gujarat-based facility serving PAN India

Trusted by industries in Ahmedabad, Vadodara, Rajkot, Surat, Bharuch, Ankleshwar, and beyond. When you choose ARKA, you are choosing enhanced tool life, improved performance, and reliable production for your critical components.

Our experts recommend ALTIFOR coating for extreme wear resistance, high-strength steel forming, and extended tool life.

| Property | Specification |

| Nano Hardness(GPA) | 34 |

| Coating Thickness | 2 – 8 μm |

| Friction Coefficient | 0.35 |

| Max Service Temperature | 900°C |

| Color Appearance | Violet Grey |

| Process Temperature | 400-500°C |

Here are some answers to common questions about our services. With our advanced processes and commitment to quality, you can be confident that your tin coating are in expert hands.

ALTIFOR is an advanced AlTi-based PVD coating designed for high-performance cutting and forming applications. It offers ultra-high hardness (up to 3500 HV), low friction, and excellent resistance to heat and oxidation. This coating enhances tool performance by increasing wear resistance, enabling faster machining, and extending tool life in demanding production environments.

ALTIFOR coating is widely used in India's metal cutting, aerospace, automotive, and die & mold industries. It's especially effective in high-speed and high-temperature machining of hardened steels, stainless steels, and exotic alloys. The coating's durability and reliability make it ideal for CNC tools, drills, end mills, dies, and forming tools.

ALTIFOR coating is engineered to withstand temperatures up to 1100°C, making it ideal for dry machining and high-speed cutting where heat generation is significant. Its advanced thermal stability and oxidation resistance help protect cutting edges, preventing tool failure due to thermal degradation and enabling longer uninterrupted operation.

ALTIFOR significantly extends tool life, reduces friction, and allows higher cutting speeds—all of which contribute to lower production costs. By reducing tool wear and the need for frequent replacements, it helps manufacturers minimize downtime, improve surface finish quality, and increase output without compromising tool integrity.

Yes, ARKA offers ALTIFOR PVD coating services to customers throughout India, including industrial hubs like Mumbai, Pune, Bengaluru, Chennai, Hyderabad, and NCR. Our nationwide logistics support ensures reliable coating solutions, fast turnaround times, and consistent quality for manufacturers in all major sectors.

Yes, we serve industries across India with PAN India shipping and coating services.