- +91 94268 85636

- Mon to Sat: 9.00 am - 6.00 pm

PVD Coating, or Physical Vapor Deposition, is a high-tech way to finish a surface that makes a thin but very strong protective layer on a product. As one of the best pvd coating companies in India, we use a state-of-the-art vacuum chamber to put materials like titanium, chromium, or carbon on your equipment and parts. This procedure gives the item a "super-skin" that makes it better without changing its shape.

Our solutions are meant to give businesses in Gujarat and all throughout India a decisive edge over their competitors. Our goal as a top pvd coating manufacturer is to give you the best pvd coating and help your products reach their full potential.

Our coatings make your parts last longer by making them more resistant to wear and tear.

The PVD film is substantially harder than the base material, therefore it protects against scratches and wear.

It protects against rust and corrosion quite well, even in tough conditions.

The best PVD coating makes things slide more easily, which can make tools work better and more efficiently.

Welcome to ARKA PVDCoating. We are one of the best PVD coating companies in India. We offer cutting-edge coating solutions that will improve the performance and lifespan of your industrial parts. We have a range of specialty coatings, each with its own set of features that can fulfill your needs.

Our versatile titanium nitride tin pvd coating is known for its high hardness and low friction, making it ideal for both metal-cutting and forming tools.This coating significantly improves tool life and performance.

Our premium ALCRN PVD coating services provide exceptional wear and heat resistance, ideal for high-speed machining and tough materials. We ensure long-lasting tool life.

Aluminum Titanium Nitride coating is highly resistant to both wear and oxidation, improving the performance of drills, mills, and inserts.This enhances tool life.

Nano composite coating is designed for machining extremely hard materials (over 50 HRC), offering excellent sticking power and low friction for high-speed applications.

ALTIFOR PVD coating services are perfect for extending the life of forming tools used with high-strength steel, preventing galling and wear. It guarantees durability

The TASC PVD Coating is a multi-functional solution designed to increase long-term cost-effectiveness and productivity, making it an excellent investment.

The DLC PVD coating service creates a very hard, carbon-based film with exceptional properties, including very low friction and high hardness. It enhances durability.

Our industrial hard coatings are engineered for cutting tools, dies & molds, aerospace components and automotive parts requiring superior wear resistance and thermal stability. We provide advanced PVD hard coating services across India using ISO-certified processes.

| COATINGS | TiN (Titanium Nitride) Hard Coating | TiAlN Hard Coating | AlCrON Hard Coating | TiSiN Hard Coating | AlTiFor Hard Coating | Tasc Hard Coating |

|---|---|---|---|---|---|---|

| Hardness (GPA) | 23 | 32 to 35 | 33 to 36 | 35 to 40 | 34 | 33 |

| Thickness (Microns) | 1 to 4 μm | 2 to 4 μm | 2 to 5 μm | 1 to 4 μm | 2 to 8 μm | 4 to 8 μm |

| Friction Coefficient | 0.5 | 0.5 | 0.5 | 0.4 | 0.35 | 0.35 |

| Color | Gold | Purple Black | Grey | Copper | Violet Grey | Grey |

| Max Service Temperature | 600 °C | 900 °C | 1000 °C | 1100 °C | 900 °C | 900 °C |

| Process Temperature | 200-400 °C | 400-500 °C | 400-500 °C | 400-500 °C | 400-500 °C | 450 °C |

| Key Characteristics | High Toughness, High adhesive strength, Low thermal conductivity, Low coefficient of friction, Excellent wear resistance | Highly resistance to wear and oxidation, Broad application range, Improved abrasion resistance, Ideal for wet and dry machining, Enhanced productivity | Covers wide range of applications, Suitable for different work piece, material, Very high wear resistant at high temperature, Heat resistant and tough | Nano composite with Si content, Good hardness, Reduces adhesion between, cutting edges and work piece , Versatile application possibilities, High speed machining | High Hardness, An optimized hardness to residual compressive stress ratio, Excellent wear resistance, Improved chemical and thermal resistance | Reduced soldering, Increased service life, Better de-moulding, Delayed heat checking, Less erosion |

| Primary Applications | Iron Alloys Steels, HSS Tools,Taps, Shaper Cutters,Cold Forming Tools | Drilling and milling in cast iron,Stainless steel,Steels upto 50 HRC,Cutting inserts | Gear cutting, Chip less forming, Cutting High tensile steels, Cast irons, Tool steels, Stainless steel Titanium and Nickel Alloys Wet and Dry machining | Drilling and Milling of steels up to 65 HRC, Stainless steel, high Nickel content alloys and Titanium | Forming of High strength steel sheet. Sheet metal forming Hot & cold forming, Drawing, Aluminum profile extrusion. | Die casting & MIM Hot forging |

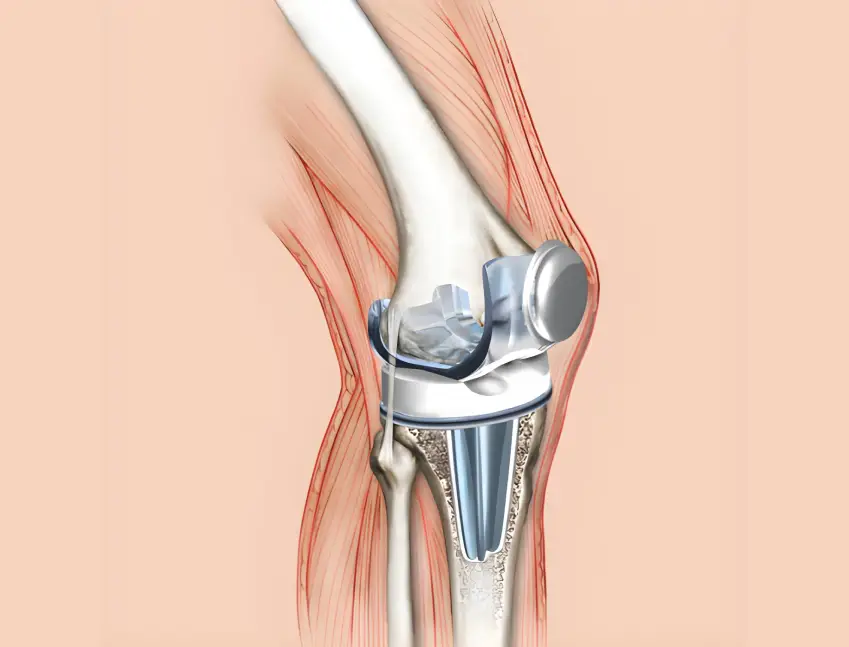

A variety of industries, from general manufacturing to more niche ones like aerospace and medicine, can benefit from ARKA PVDCoating's PVD coating services.

We offer PVD coating for cutting tools that makes them last much longer and work better. We put our coatings on a lot of different equipment, such drills, end mills, reamers, taps, and saws. Our TiN coating for cutting tools is ideal for both HSS and carbide tools.

Read More

We are experts in PVD coating for extrusion dies and PVD coated molds. Our coatings work great for die casting tools and plastic molding applications, like cavities, cores, and ejector pins. Our remedies make things less likely to wear out and stop galling.

Read More

We are one of the best companies that offers automotive PVD coating services. We put long-lasting, wear-resistant coatings on a lot of different parts, such as engine parts like pistons and gears. We also cover sections of the transmission, fasteners, and fuel system injectors.

Read More

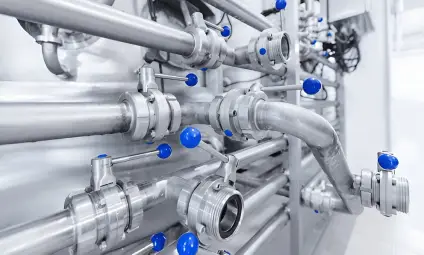

We offer industrial coatings for the energy sector, such as pvd coating for parts used in oil and gas and power generation. Our products make drilling equipment, pumps, and valves last longer in very harsh conditions.

Read MoreExperience(Years)

Advanced Coating Solutions

Commitment To Quality

Client Satisfaction Rating

Our PVD coating process shows how much we care about quality and accuracy. We are one of the best providers of the physical vapor deposition process in India.

We carefully clean the parts by getting rid of dirt & grease to make sure the coating sticks to the surface. We make sure the surface is completely clean.

Parts are put in a vacuum chamber, where a solid substance is turned into gas & then deposited, making a thick, strong layer.

After the coating is applied, the items are cooled down & then carefully tested by our quality control team to make sure they fulfill all the requirements.

After passing all quality checks, the parts are securely wrapped and sent back to you, ready to work better. We deliver quality you can rely on.

Call Us 24/7