- +91 94268 85636

- Mon to Sat: 9.00 am - 6.00 pm

At ARKA PVD, we deliver advanced PVD coating services for oil, gas, and power industry tools and components across India, ensuring superior durability, heat resistance, and efficiency. Our Physical Vapor Deposition (PVD) coating applies a thin, ultra-hard protective layer that enhances wear resistance, corrosion protection, and tool life in extreme environments. Ideal for drilling tools, turbine parts, and critical components, this coating reduces downtime, cuts replacement costs, and ensures reliable performance. For industries seeking efficiency, cost savings, and long-lasting results, our PVD coatings provide the ultimate solution.

Call Us

Client Satisfaction

PVD coating for oil, gas, and power tools is a proven solution that boosts durability, efficiency, and reliability. A strong protective layer ensures your tools withstand extreme conditions, delivering longer life, reduced downtime, and superior performance in demanding industries.

PVD coatings guard tools against wear, friction, and high heat—perfect for the harsh environments of drilling, refining, and power generation.

The coating enhances hardness, reduces tool failure, and extends the service life of oilfield tools, power plant components, and gas industry equipment.

Fewer tool replacements and less downtime lower overall operational costs, making PVD coating services a smart long-term investment.

Our wear-resistant coatings ensure consistent, high-quality performance—keeping oil, gas, and power tools efficient, safe, and productive.

Our PVD coatings for oil, gas, and power industries deliver extreme wear resistance, corrosion protection, and longer tool life—ensuring reliability in the harshest environments.

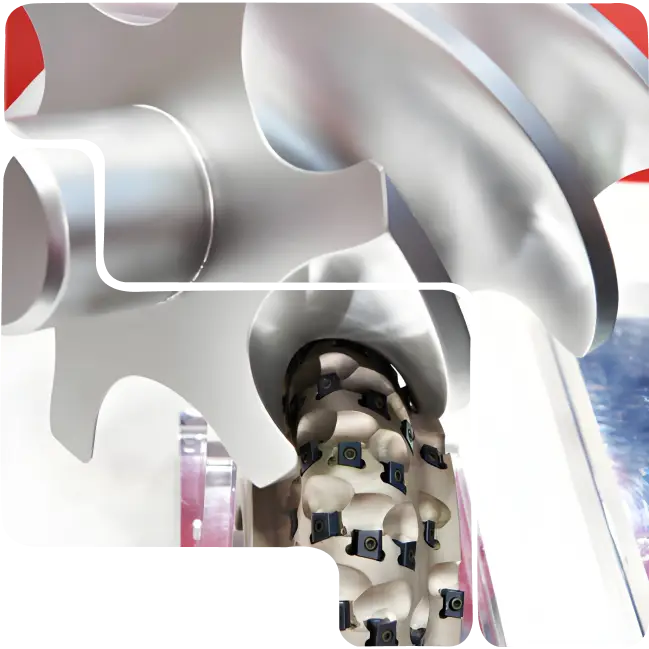

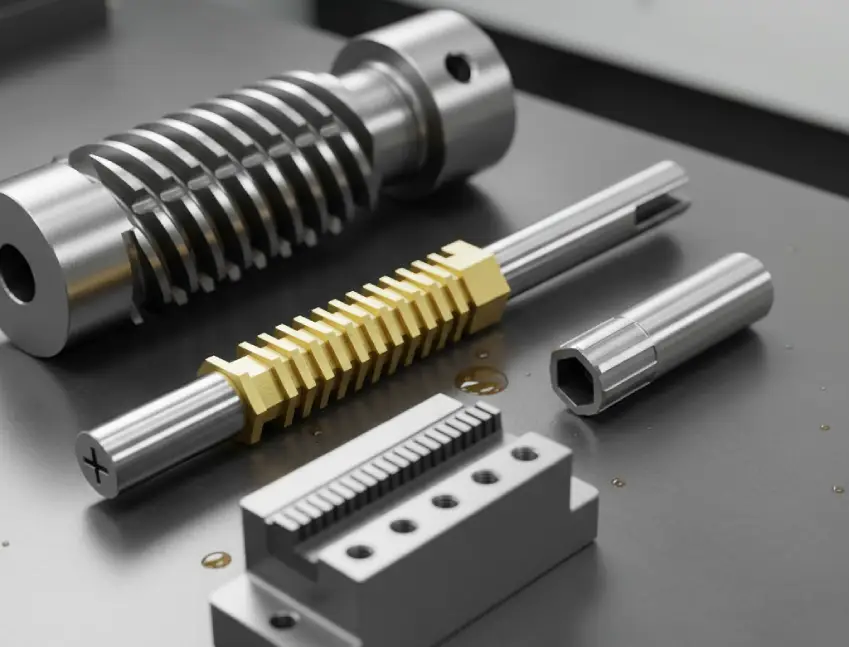

Extend tool life for oilfield broaches and inserts with our coatings, ensuring smoother operations, precise cuts, and reduced downtime.

Experience reduced friction and enhanced chip flow with coated oil & gas drills and reamers, delivering cleaner holes and longer-lasting tools.

Our PVD-coated mills and saws offer superior abrasion resistance, making them ideal for cutting tough alloys used in oil rigs and power plants.

Designed for high-load applications, coated hobs and cutters provide durability and accuracy in manufacturing heavy-duty components for energy sectors.

Coated taps ensure accurate threads in high-strength alloys, reducing torque, galling, and tool wear in demanding oil and power operations.

Whether HSS or carbide tools, our PVD coatings boost hardness and reliability—making them ideal for harsh drilling, refining, and power-generation tasks.

At ARKA, we are recognized as a trusted partner for PVD coating solutions in the oil, gas, and power industries.

Call Us

Our diverse range of specialized coatings is designed to meet needs, ensuring optimal performance for our clients. We offer a wide range of specialized coatings for specific uses, perfect for various purpose and applications. Here are some of our most popular PVD coating for oil and gas industry.

ARKA TIN PVD Coating

Our versatile titanium nitride tin pvd coating is known for its high hardness and low friction, making it ideal for metal-cutting and forming tools.

Read MoreARKA ALCRON PVD Coating

We offer premium alcrn pvd coating services that provide exceptional wear and heat resistance for high-speed machining and tough materials.

Read MoreARKA TALIN PVD Coating

Aluminum Titanium Nitride coating is highly resistant to both wear and oxidation, improving the performance of drills, mills, and inserts.

Read MoreARKA TISIN PVD Coating

Nano composite coating is designed for machining extremely hard materials (over 50 HRC), offering excellent sticking power and low friction for high-speed applications.

Read MoreARKA ALTIFOR PVD Coating

ALTIFOR PVD coating services are perfect for extending the life of forming tools used with high-strength steel, preventing galling and wear.

Read MoreARKA TASC PVD Coating

The TASC PVD Coating is a multi-functional solution designed to increase long-term cost-effectiveness and productivity, making it an excellent investment.

Read MoreDLC PVD Coating

The DLC PVD coating service creates a very hard, carbon-based film with exceptional properties, including very low friction and high hardness.

Read MoreHere are some answers to common questions about our services. With our advanced processes and commitment to quality, you can be confident that your Oil & Gas / Power are in expert hands.

PVD coating for oil, gas, and power equipment increases hardness, reduces friction, and prevents corrosion. It ensures reliable operation and extended service life in extreme industrial environments.

PVD coating on oil and gas components typically lasts several times longer than uncoated parts. It withstands high pressure, temperature, and abrasive conditions common in drilling and energy operations.

The benefits of PVD coating include reduced wear, improved heat resistance, and superior corrosion protection. It minimizes downtime, lowers maintenance costs, and boosts efficiency in critical energy operations.

PVD coating is widely applied to drilling tools, turbine blades, valves, and pump components. It enhances performance, extends service life, and ensures reliable operation in high-stress environments.

ARKA PVD Coating delivers advanced surface solutions designed for oil, gas, and power equipment. Our coatings provide maximum durability, reliability, and efficiency in the toughest industrial conditions.