- +91 94268 85636

- Mon to Sat: 9.00 am - 6.00 pm

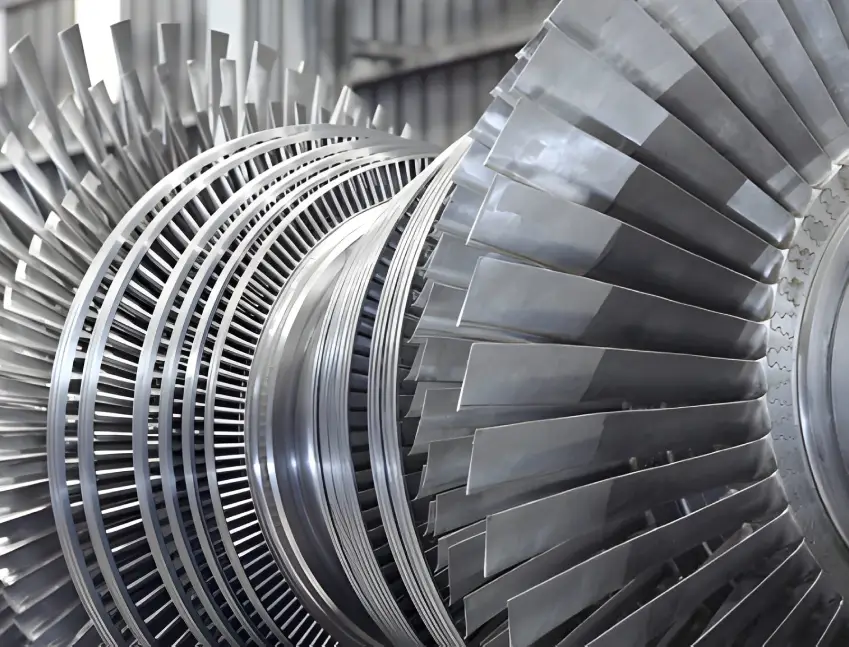

Our ultrathin PVD coatings for aerospace parts are engineered with precise 1–4 micron thickness control to enhance wear resistance, reduce friction and withstand extreme thermal cycling. Designed for turbine blades, landing gear systems, fasteners and structural aerospace components, these micro-layer coatings deliver durability without altering critical dimensions. ARKA PVD Coating provides high-performance aerospace coating solutions across Gujarat and India, ensuring reliability, precision and long service life in demanding flight environments..Learn more about the PVD process here.

Call Us

Client Satisfaction

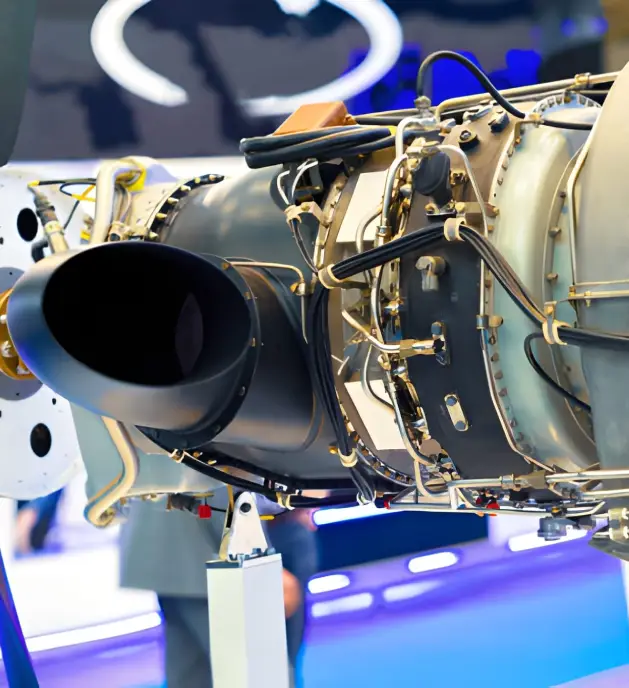

PVD coating for aerospace parts is a mission-critical solution. Its benefits for aviation & aerospace applications are unmatched, providing a protective layer that increases durability, reliability, & performance of aerospace engine & structural components.

Aerospace PVD coating delivers exceptional hardness & wear resistance, safeguarding turbine blades, engine parts, & landing gear from high stress, heat, & friction.

Anti-friction aerospace coatings reduce drag and improve efficiency, ensuring smoother operations under extreme temperatures and pressure.

Our PVD coating solutions provide significant cost savings for airlines, defense aviation, and aerospace OEMs.

PVD coating ensures precision, consistency, and safety for aerospace parts, meeting strict aviation standards.

We offer high-performance aerospace PVD coatings and surface treatment solutions tailored for critical aviation and aerospace tools, boosting their durability, performance, and reliability.

Our PVD coating for turbine blades ensures resistance to extreme heat, oxidation, and wear, extending the life of jet engine components.

High-strength aerospace fasteners gain superior hardness and anti-corrosion properties, ensuring long-term reliability in flight operations.

PVD coating for landing gear improves wear resistance and reduces friction, supporting heavy loads and repeated stress cycles.

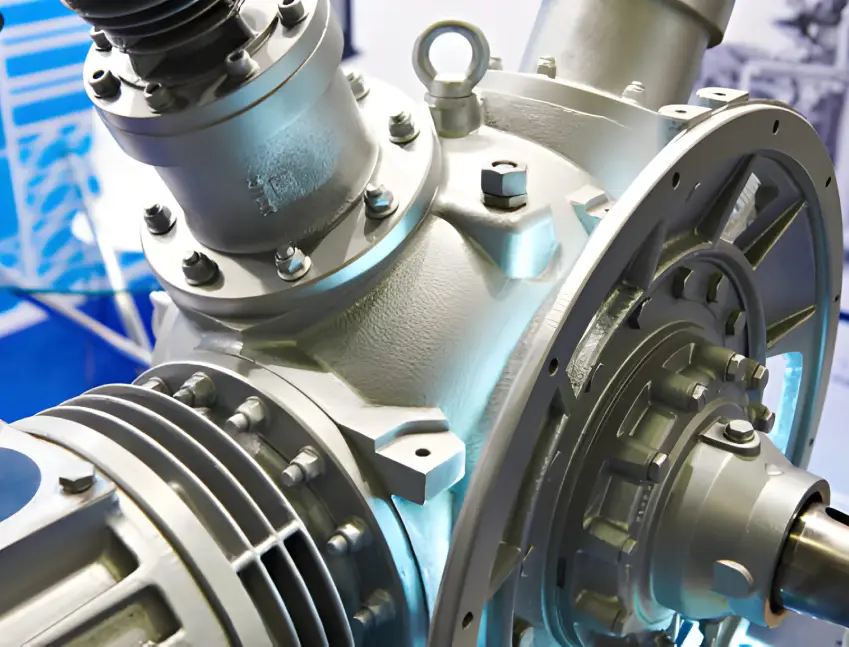

Critical compressor blades, seals, and pump parts benefit from reduced friction and enhanced corrosion protection.

Precision cutting tools for aerospace machining get improved sharpness retention, reducing downtime and boosting productivity.

PVD coatings deliver a high-quality finish with strong protection, ensuring performance and reliability for sensitive aerospace systems.

At ARKA, we are recognized as a trusted partner for PVD coating solutions in the aerospace industry.

Call Us

Our specialized aerospace coatings are engineered to meet the demanding requirements of flight and space applications. We offer a wide range of PVD coatings tailored for extreme conditions, ensuring reliability, durability, and peak performance.

ARKA TIN PVD Coating

Our versatile titanium nitride tin pvd coating is known for its high hardness and low friction, making it ideal for metal-cutting and forming tools.

Read MoreARKA ALCRON PVD Coating

We offer premium alcrn pvd coating services that provide exceptional wear and heat resistance for high-speed machining and tough materials.

Read MoreARKA TALIN PVD Coating

Aluminum Titanium Nitride coating is highly resistant to both wear and oxidation, improving the performance of drills, mills, and inserts.

Read MoreARKA TISIN PVD Coating

Nano composite coating is designed for machining extremely hard materials (over 50 HRC), offering excellent sticking power and low friction for high-speed applications.

Read MoreARKA ALTIFOR PVD Coating

ALTIFOR PVD coating services are perfect for extending the life of forming tools used with high-strength steel, preventing galling and wear.

Read MoreARKA TASC PVD Coating

The TASC PVD Coating is a multi-functional solution designed to increase long-term cost-effectiveness and productivity, making it an excellent investment.

Read MoreDLC PVD Coating

The DLC PVD coating service creates a very hard, carbon-based film with exceptional properties, including very low friction and high hardness.

Read MoreHere are some answers to common questions about our services. With our advanced processes and commitment to quality, you can be confident that your cutting tools are in expert hands.

PVD coating provides aerospace parts with superior wear resistance, corrosion protection, and thermal stability, ensuring reliable performance in extreme flight conditions.

Common applications include turbine blades, fasteners, landing gear, and engine parts, where coatings improve durability and reduce maintenance costs.

By increasing hardness, reducing friction, and enhancing resistance to heat and oxidation, PVD coatings help maintain consistent performance and safety.

ARKAPVD uses advanced PVD technology and strict aerospace standards to deliver precision coatings, ensuring longer part life and reduced downtime.

Yes, ARKAPVD offers tailored coating solutions based on component type, operating conditions, and performance requirements of the aerospace industry.