- +91 94268 85636

- Mon to Sat: 9.00 am - 6.00 pm

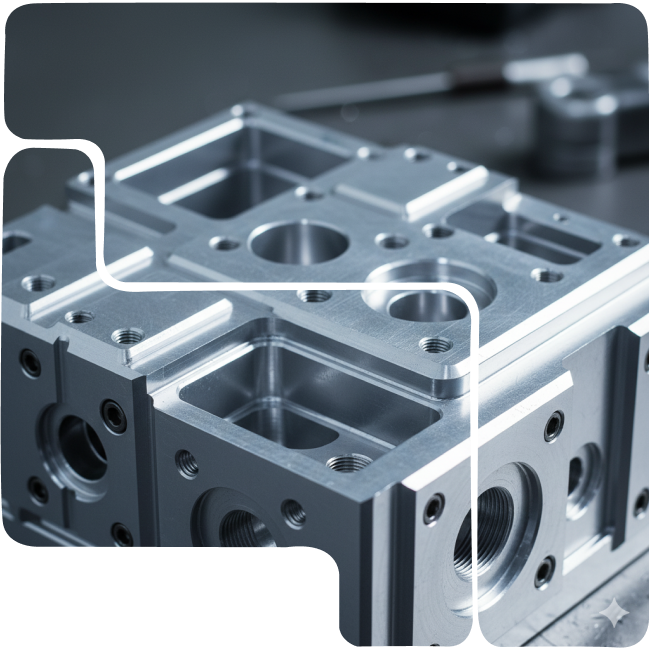

When it comes to enhancing the life and performance of your dies and molds, the right surface treatment is vital. ARKA PVDCoating is a leading provider of premium PVD coating solutions tailored for a diverse range of industrial applications. Our PVD coated molds and dies are designed to protect against wear and improve productivity. The right PVD coating is the ideal mold surface treatment for your tools, no matter the job. With our advanced technology and commitment to excellence, we deliver wear resistant coating for dies and molds in India.Learn more about the PVD process here.

Call Us

Client Satisfaction

PVD coating is a critical solution for dies and molds. It provides a strong, protective layer that enhances mold tool life improvement coating and ensures your tools perform better and last longer.

PVD coatings provide a hard surface protecting tools from abrasion & heat. This ensures a wear resistant coating for dies and molds.

The coating boosts hardness and reduces friction, leading to better part release and smoother, more efficient operation.

Extend tool life, reduce replacements, and lower production downtime, saving you time and costs long-term.

A coated die or mold helps you get consistent, high-quality results on every job. This also helps improve the finish on formed parts.

Our coatings can be applied to many different types of dies and molds to boost their performance:

We provide PVD coating for extrusion dies to reduce pick-up, galling on tool surfaces. This also helps reduce downtime for maintenance.

Our coatings protect surface finish from damage and improve material flow. We also provide coatings for injection molding tools.

Our coatings improve wear resistance and part release. We also provide AlCrN coating for hot forging dies to reduce soldering.

Our coatings for cores, dies, and punches improve cutting edge retention, which leads to a longer tool and a die life.

Our specialized coatings provide resistance to high heat and wear, which are common issues, enhancing the life of your forging dies.

Our coatings for blanking dies improve their durability and reduce friction, leading to cleaner cuts and a longer tool life.

At ARKA, we stand out as the top choice for your PVD coating needs.

Call Us

We offer a wide range of specialized mold coatings for specific uses, perfect for various dies and molds and their applications. Here are some of our most popular PVD coatings for dies and molds:

ARKA TIN PVD Coating

Our versatile titanium nitride tin pvd coating is known for its high hardness and low friction, making it ideal for metal-cutting and forming tools.

Read MoreARKA ALCRON PVD Coating

We offer premium alcrn pvd coating services that provide exceptional wear and heat resistance for high-speed machining and tough materials.

Read MoreARKA TALIN PVD Coating

Aluminum Titanium Nitride coating is highly resistant to both wear and oxidation, improving the performance of drills, mills, and inserts.

Read MoreARKA TISIN PVD Coating

Nano composite coating is designed for machining extremely hard materials (over 50 HRC), offering excellent sticking power and low friction for high-speed applications.

Read MoreARKA ALTIFOR PVD Coating

ALTIFOR PVD coating services are perfect for extending the life of forming tools used with high-strength steel, preventing galling and wear.

Read MoreARKA TASC PVD Coating

The TASC PVD Coating is a multi-functional solution designed to increase long-term cost-effectiveness and productivity, making it an excellent investment.

Read MoreDLC PVD Coating

The DLC PVD coating service creates a very hard, carbon-based film with exceptional properties, including very low friction and high hardness.

Read MoreHere are some answers to common questions about our services. With our advanced processes and commitment to quality, you can be confident that your dies and molds are in expert hands

PVD coatings for injection molding tools provide a hard, wear-resistant layer that protects the mold surface finish. This reduces friction, improves the flow and release of materials, and decreases downtime for cleaning and maintenance.

AlCrN coating for hot forging dies provides exceptional resistance to high heat, oxidation, and wear. It is specifically designed to reduce the tendency for soldering (material sticking to the die), which is a common problem in hot forging operations.

Yes, PVD coatings are highly effective for sheet metal forming. They provide an optimized balance of hardness and stress resistance, which reduces friction and galling on the die surface. This leads to smoother forming processes and a longer tool life.

The best PVD coating for dies and molds depends on the specific application. At ARKA, we offer a range of specialized coatings, such as ARKA TASC for hot forging and die casting, and ARKA TALIN for high-hardness materials. Our experts can help you select the ideal coating for your needs.

Yes, many of our PVD coatings are specifically designed for high-temperature applications. Coatings like ARKA ALCRON and ARKA TALIN provide excellent heat resistance coatings for dies, preventing them from degrading under the high thermal stress common in processes like hot forging and die casting.